Wellhead Tools: Quality Solutions from Leading Manufacturers and Trusted Factories

When it comes to high-quality wellhead tools, WUXI TAKELO MACHINERY CO., LTD. is a reliable manufacturer. Their comprehensive range of wellhead tools is specifically designed to meet the demanding needs of the oil and gas industry. Each product is precision-engineered to ensure both efficiency and safety in operations. WUXI TAKELO's commitment to quality is evident throughout their offerings, supported by a robust supply chain that guarantees timely delivery and exceptional customer service. Partnering with WUXI TAKELO means aligning with a company that fully understands the unique challenges faced by B2B purchasers in our sector. Enhance your operations and productivity with their advanced wellhead tools.Key Methods For Wellhead Tools Pioneers in the Field Factory-Direct Excellence

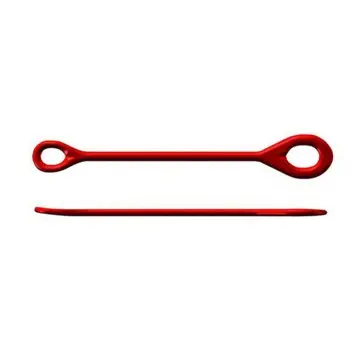

In today's competitive landscape, the demand for high-quality wellhead tools is rapidly growing, prompting pioneers in the field to seek factory-direct solutions that not only enhance operational efficiency but also ensure reliability. One of the key methods to achieve this excellence is through innovative equipment tailored to the specific needs of the oil and gas industry. The right machinery, such as swage machines and hydraulic make-up & Breakout Machines, is crucial for maximizing productivity while minimizing downtime. Moreover, integrating advanced threading machine conveyors and handling systems can significantly streamline operations. These systems provide seamless transition and processing of wellhead tools, allowing manufacturers to maintain high output levels without compromising quality. Additionally, painting and marking systems ensure that every piece of equipment meets regulatory standards and is easily identifiable in challenging environments. Investing in state-of-the-art machinery demonstrates a commitment to quality and performance, positioning manufacturers as leaders in the wellhead tools market. As global buyers increasingly prioritize sustainability and efficiency, leveraging factory-direct excellence becomes not just a competitive advantage, but a critical component in meeting the demands of the evolving energy sector.

Key Methods For Wellhead Tools Pioneers in the Field Factory-Direct Excellence

| Method | Description | Benefits | Implementation Time |

|---|---|---|---|

| Direct Sourcing | Identify and procure tools directly from manufacturers. | Cost savings, quality assurance, and quicker turnaround. | 1-2 weeks |

| Quality Control Processes | Establishing rigorous testing and inspection protocols. | Improved reliability and reduced failure rates. | 2-4 weeks |

| Technical Training | Providing comprehensive training for staff on tool usage. | Enhanced operational efficiency and safety. | Ongoing |

| Customer Feedback Loop | Collecting and analyzing customer feedback on tools. | Product improvement and increased customer satisfaction. | 1-3 weeks |

| Innovation Workshops | Conducting workshops to brainstorm new tool solutions. | Fostering a culture of creativity and continuous improvement. | 1 week |

In-Depth Analysis of Methods Wellhead Tools Manufacturer Where Service Meets Innovation

B

Brian Wilson

Very reliable service! The staff was well-informed and helped me navigate my concerns effortlessly.

18 June 2025

L

Logan Stewart

Kudos to the customer service team! They go above and beyond for their clients.

23 June 2025

E

Ella Robinson

An exceptional product! The after-sales service was just as impressive.

28 May 2025

A

Abigail Murphy

Their service team was incredibly helpful. I felt valued as a customer.

09 May 2025

L

Luna Reed

Great product with superb quality! They really understand their market.

15 June 2025

L

Lucas Ward

Extremely pleased with my purchase. The quality was fantastic!

23 May 2025