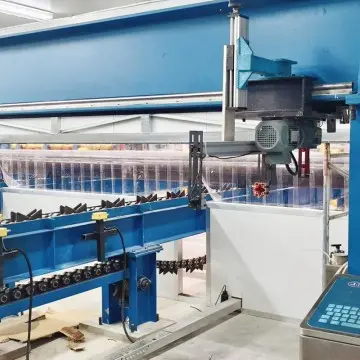

Tubular Airless Painting(Spraying) production line

Prodcut Features:

1. Intelligent Spray Technology: Auto-calibrating spray guns with diameter-adaptive extensions to accommodate different pipe diameters. The spray guns we adopted is Chinese and world famous brand.

2.Coating efficiency system: The System is designed for overspray recovery rate reach to 98% and closed-loop recycling with automatic viscosity compensation.

3. Production Optimization: The innovative design enables faster production line speeds for increased productivity.

4. Auto Cleaning Systems: Auto cleaning starts if the machine stops working for 4 hours, save time for production.

5. Curing Systems: There is Intermediate frequency furnace and inductive coil if necessary to speed up the the coating drying time.

6. Automatic Handling Equipment: Automatic systems often include conveyors and other handling equipments to move steel pipe through the various stages of the painting process.

Industry Applications

Casing & tubing (API 5CT)

Drill pipe & collars (API 7-1)

Seamless pipes for offshore platforms

High-strength steel components (X80+ grades)

There are three models:

Paint type |

water-based (oil-based) hard film anti rust coating |

Painting form |

high-pressure airless automatic spraying |

Compressed air pressure |

≥ 0.6Mpa |

Coating thickness |

10-35 μ m (dry film) |

Paint viscosity |

Apply four cups for 24-30s |

Coating fineness |

greater than or equal to 260 mesh |

Oil coating quality |

Strong adhesion, uniform outer surface, no leakage or dripping |

Spray speed |

0.8-1.0m/s |

Application Industry |

Casing&Tubing, Drill pipe, Drill collar, Seamless pipe |

Auxiliary Device |

In-feeding conveyor before painting, out-feeding conveyor after panting, WISTON Alignment Device, Drying table, Automatic Marking Machine,Stepping Motion Mechanism,PLC integrated control system for whole system |