Pipe Weighing Equipment Manufacturer

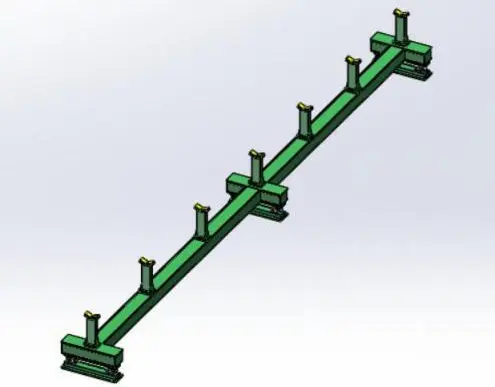

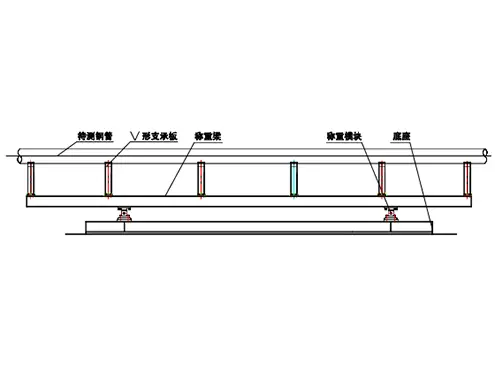

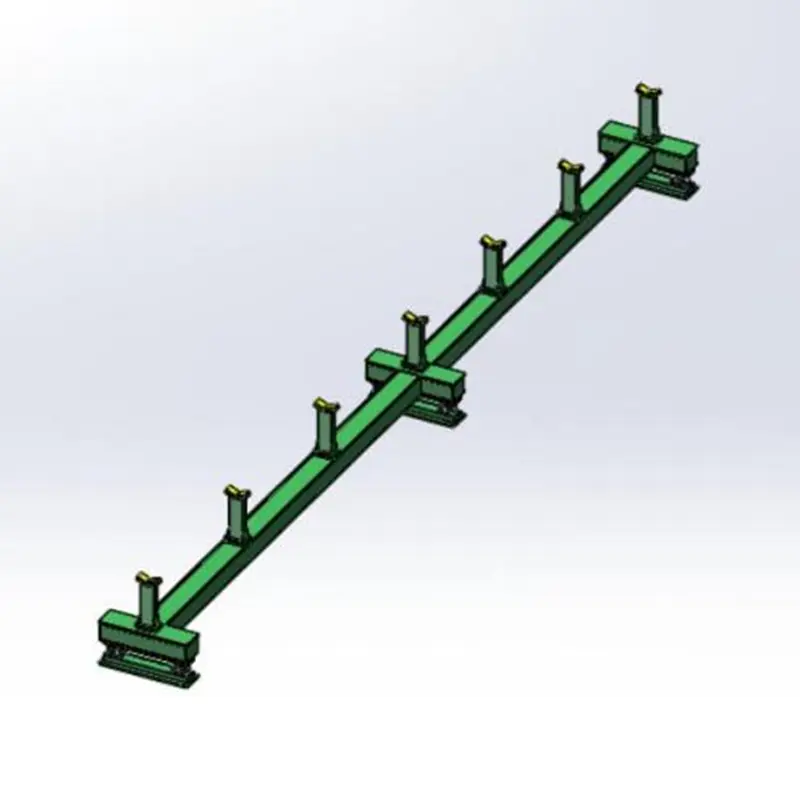

Key Features of the Weighing Machine

Automatic Weighing: The system automatically measures the weight of each steel pipe, ensuring accurate weight calculation.

High Accuracy and Repeatability: The system delivers high repeatability and precision in length measurement and weight calculation.

Data Storage and Querying: All data is securely stored in a database, enabling easy and quick access for future reference. Historical data can be analyzed and visualized in graphical formats.

Data Traceability: Steel pipe production is organized by contract numbers, pipe numbers, and furnace batch numbers, allowing full traceability of each pipe’s production data.

Comprehensive Alarm System: The system features an advanced alarm function to ensure that no pipes are missed during measurement and labeling, preventing errors in the production process.

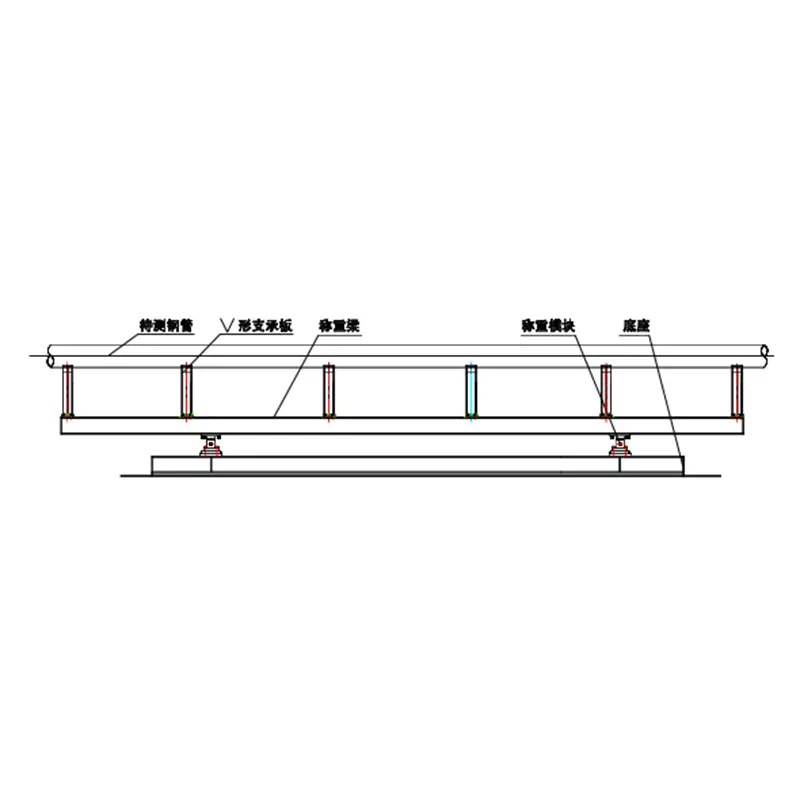

Pipe Weighing Machine Specifications

Weighing range |

100~3000kg |

Pipe weight |

≤250kg ±0.25kg |

Pipe weight |

250kg~1000kg ±0.5kg |

Pipe weight |

1000kg~2500kg±0.75kg |

Pipe weight |

2500kg~3000kg±1kg |

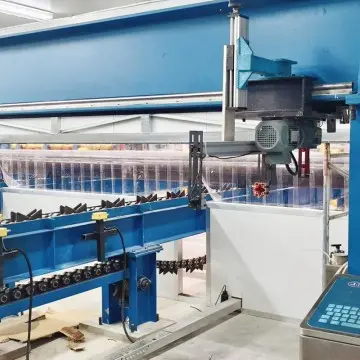

Application Benefits

This Pipe Weighing Equipment is meticulously designed to deliver exceptional accuracy, reliability, and efficiency, positioning it as an indispensable tool for steel pipe manufacturers. By automating critical processes such as weighing, length measurement, and labeling, it significantly streamlines production workflows. The advanced data storage and traceability features enable manufacturers to maintain stringent quality control standards while enhancing operational productivity. With its user-friendly interface and robust performance, this system not only improves the accuracy of measurements but also minimizes the risk of errors, ensuring consistent product quality and timely deliveries.