Pipe Rust Removal system/Derusting machine manufacturer

Key Capabilities

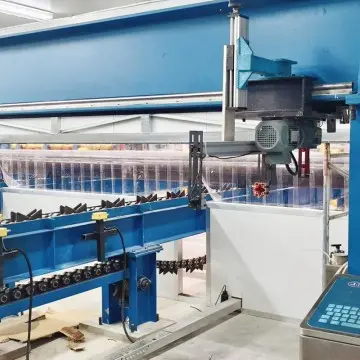

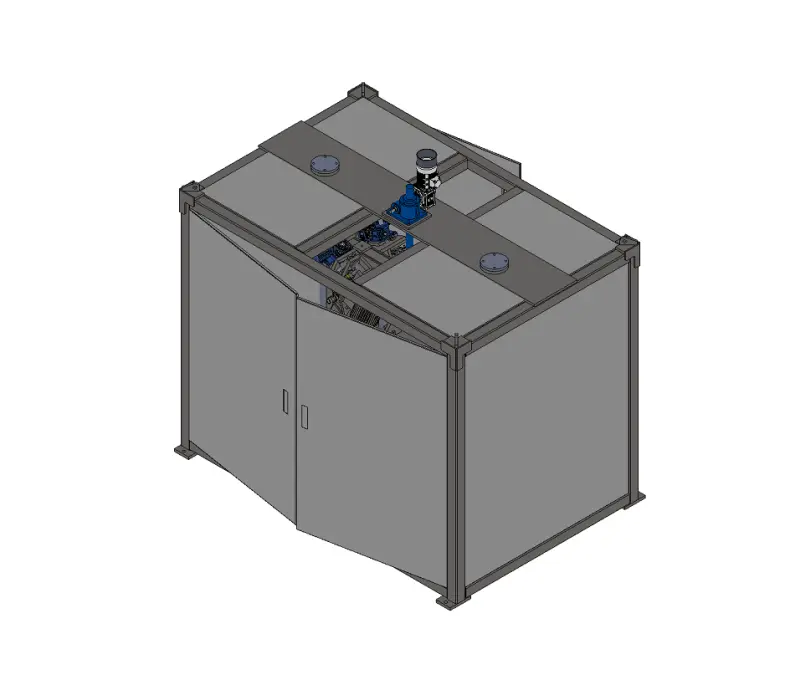

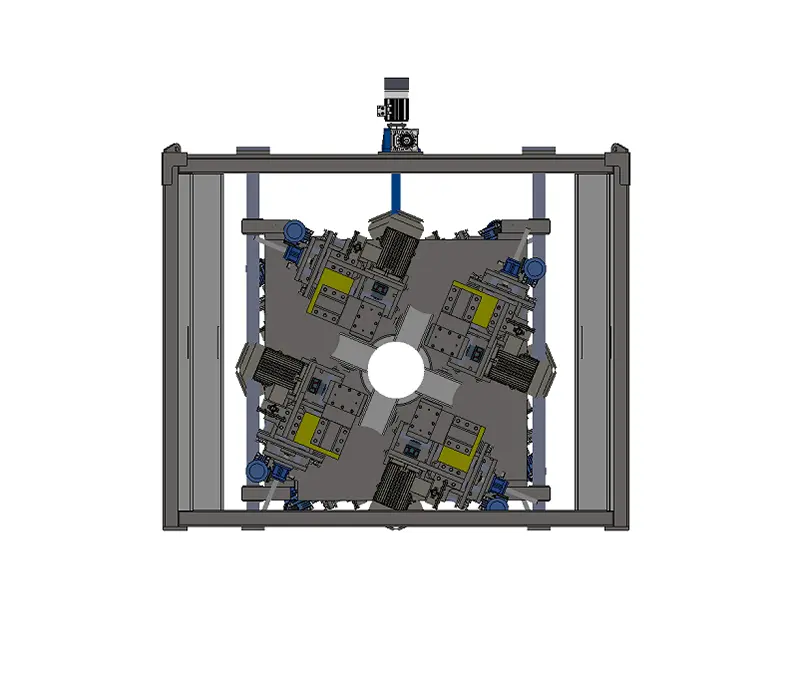

Derusting Machine

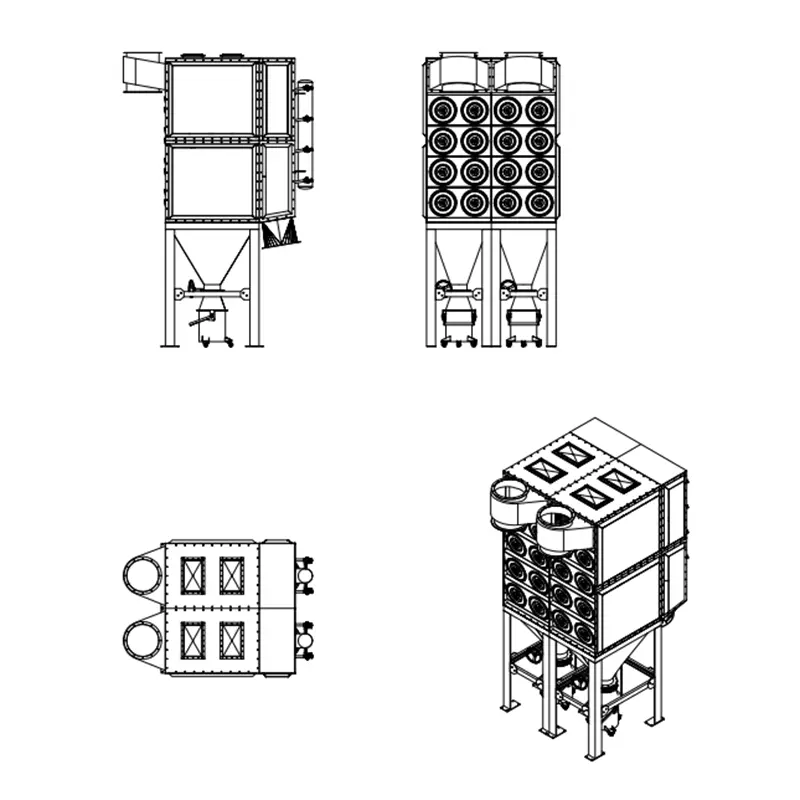

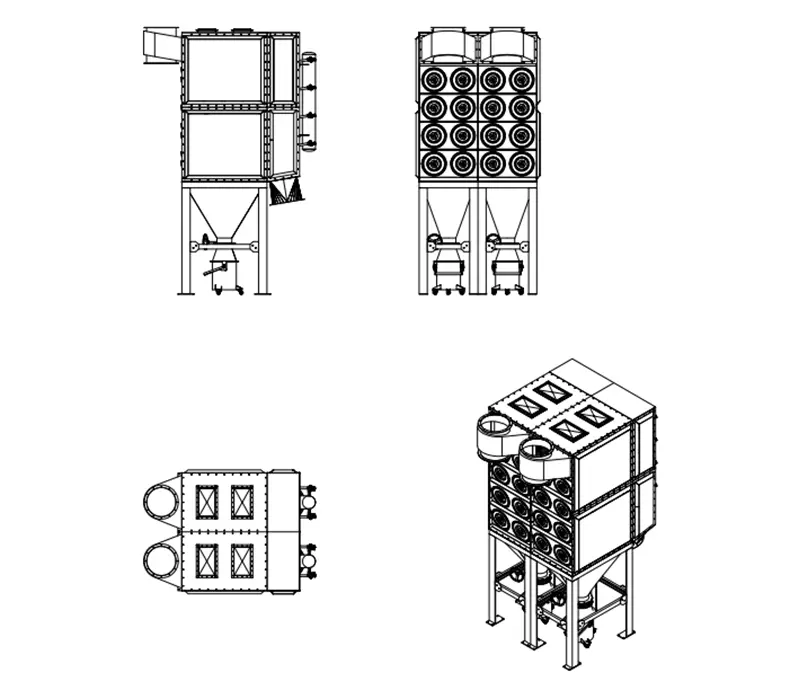

Pulse Cartridge Dust Collector

Features of the Derusting Machine/Rust Removal

High-Speed Derusting Performance

Working Principle: Rust is stripped away via physical friction or impact force.

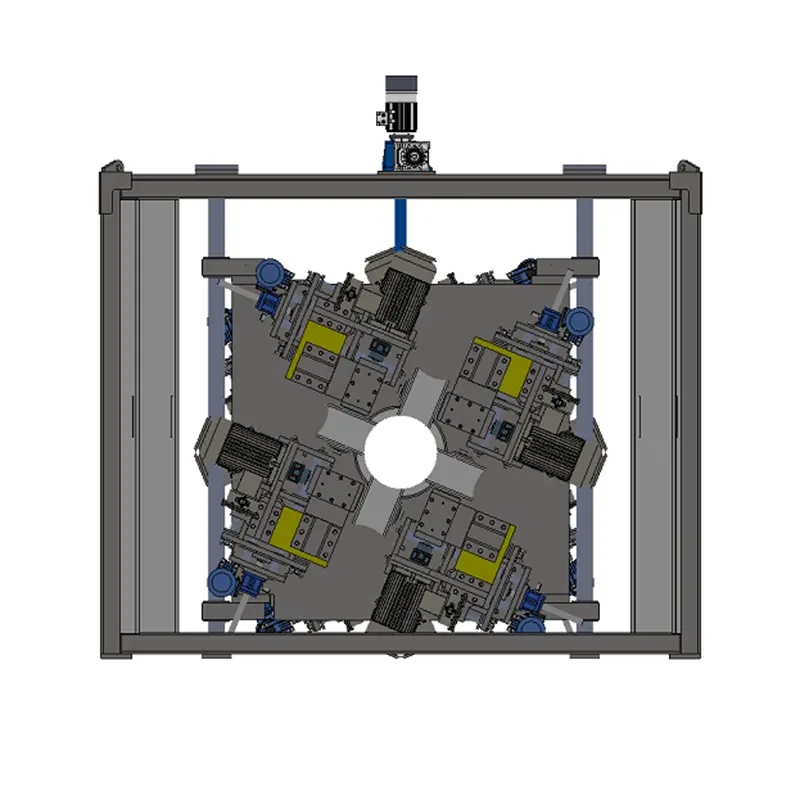

Wire Brush Derusting Mechanism:

Rotating wire brushes directly rub against the pipe surface, making it ideal for long, continuous workpieces like Casing and Tubing.

Each derusting grinding head assembly includes: arc-shaped wire brushes, spindle box, coupling, motor, guide shaft, buffer springs, and a lifting device. The wire brushes are customized to match different pipe specifications—pipes with similar dimensions can share the same arc-shaped wire brush, enhancing versatility.

High efficiency and strong adaptability to various tubing/casing sizes, and clean the pipe surface.

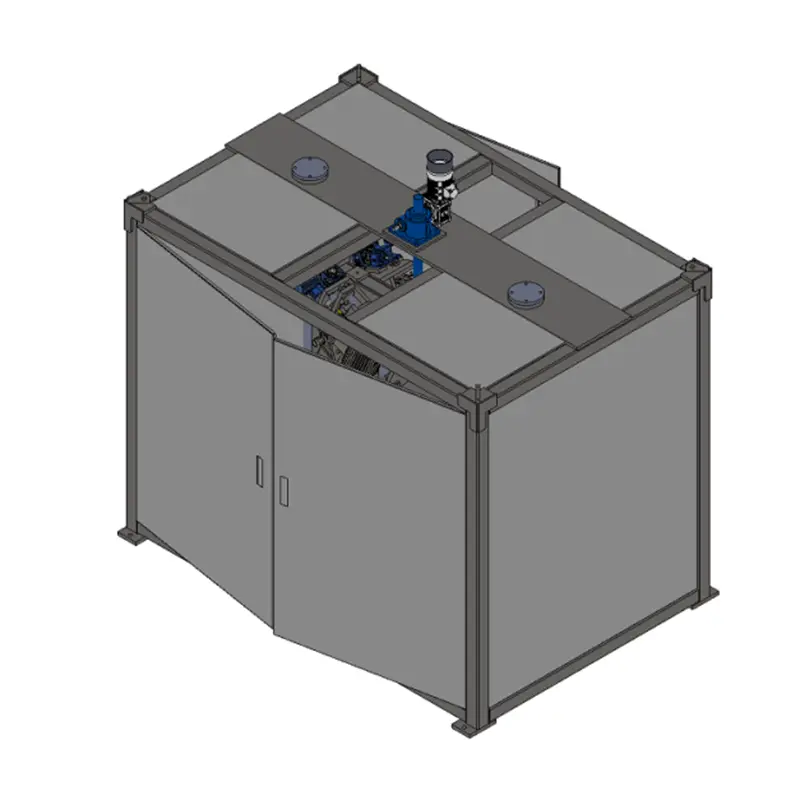

Dust Collection System

Dust-laden air first enters the cyclone dust collector through the central air inlet, where a portion of the dust is separated using wind force and gravity. The remaining air then flows into the cartridge dust collector’s cabinet. As the air volume suddenly expands, airflow velocity drops sharply—larger dust particles settle into the lower hopper under their own weight. The remaining fine particles are trapped on the outer surface of the filter cartridges via a combination of screening, collision, adhesion, diffusion, and electrostatic effects.

Cleaned air passes through the filter cartridges and is exhausted through the upper cabinet’s outlet via pipes. Over time, accumulated dust on the cartridges increases system resistance. To keep resistance within acceptable limits, a pulse controller triggers electromagnetic pulse valves sequentially, releasing compressed air from the air tank. This air is jetted through nozzles into the center of each corresponding cartridge (primary air), which in turn induces several times more surrounding air (secondary air) to enter the cartridge. This causes the cartridge to expand rapidly; once the reverse pulse impact fades, the cartridge contracts sharply. This expansion-contraction cycle dislodges excess dust from the cartridge surface, which then falls into the hopper and discharge through the ash discharge system—effectively cleaning the cartridges.

This system combines robust derusting capability with efficient dust control, ensuring clean, precise, and high-performance operation for Pipe maintenance.

Pipe Rust Removal system/Derusting machine Specification

Spindle motor |

4KW |

Center height adjustment motor |

1.1KW |

Wire brush specification adjustment motor power |

0.37KW |

Total machine power |

35KW |

Equipment center height |

1000mm-1350mm |

Universal steel pipe specifications |

60.3-340 |

Steel pipe derusting linear speed |

0.2m-1.0m/s |

Main machine dimension |

2.9m1.9m2.3m |

Derusting dimension |

1.6m2.0m4.5m |

Suction fan power of dust collection system |

22KW |

Number of filter cartridges |

|

Filter cartridge dimension |

Ø325*600mm |

Blower model |

4-72NO.4A |

Blower air volume |

10000m³/hour |

Pulse valve working pressure |

0.5-0.6MPa |

Emission concentration |

≤20mg/m³ |

Noise level |

≤65DB |

Chimney high-altitude emission |

15m |

Alarm temperature |

70℃ |

Spraying temperature |

90℃ |

Supporting booster pump pressure |

Above 0.4MPa |

Dust collector ash cleaning pressure |

Above 0.4MPa |