Pipe Inkjet Marking Equipment Manufacturer

Key Features of the Inkjet Printer

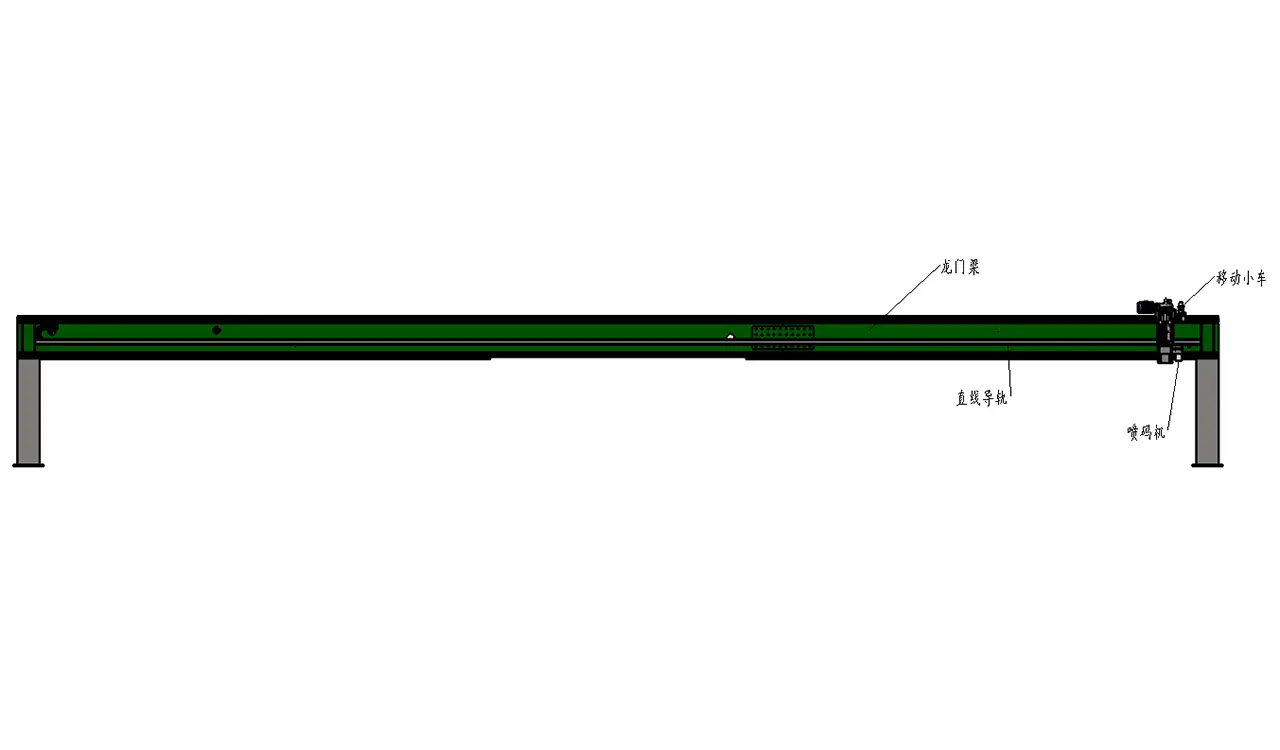

Basic Parameters of the Inkjet Marking Equipment

Category |

Item |

Specification |

Positioning Control |

Pipe End Positioning Error |

-100 mm to +200 mm |

Print Position |

Adjustable from 0 to 900 mm from the pipe end, positioning error ≤ 20 mm |

|

Print Coverage |

Full-length marking, consistent start point for each batch of pipes (based on operational parameters) |

|

Printing Parameters |

Character Height |

10 to 48 mm |

Character Count |

Up to 512 characters |

|

Character Type |

Any computer-defined characters |

|

Dot Matrix |

16-dot matrix |

|

Printing Speed |

0 to 120 m/min (bidirectional printing) |

|

Exhaust Gas Treatment |

Workstation with Fan + Activated Carbon Adsorption Unit |

Used to treat exhaust gases from marking and coating processes |

Special Interlocking Requirements |

Printer Movement Signal |

When the printer moves, the PLC sends a signal to initiate marking |

Spray Coating Trigger |

The spray coating system is activated based on the movement of the printing carriage (starting and stopping determined by print position) |

|

Measurement and Weighing Integration |

The system triggers alarms for defective pipes based on length and weight measurements (per specified requirements) |

Application Benefits