Top Non-Mag Drill Collar Manufacturers & Suppliers for Peak Performance

As a premier provider of Non-Mag Drill Collars, we prioritize precision and reliability in all drilling operations. Our top-quality products, manufactured in China with advanced technology and skilled craftsmanship, cater to contractors and engineering teams alike. Designed to enhance drilling efficiency, our drill collars offer superior weight and control across a variety of applications. At WUXI TAKELO MACHINERY CO., LTD., we are proud to serve as trusted industry suppliers, offering an extensive range of sizes and specifications tailored to meet your needs. With a commitment to customer satisfaction, we ensure you receive not only exceptional products but also comprehensive support throughout the purchasing process. Choose our Non-Mag Drill Collars to optimize your drilling projects and increase your overall productivity, and let’s collaborate to achieve your operational goals.Expert Tips For Non-Mag Drill Collar Pioneers in the Field Factory-Direct Excellence

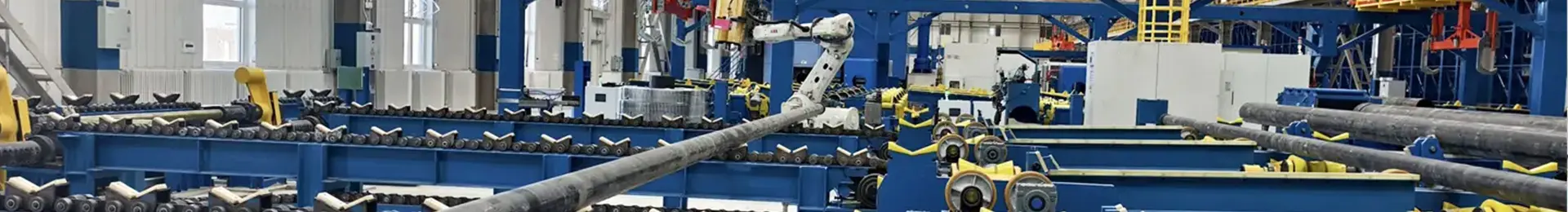

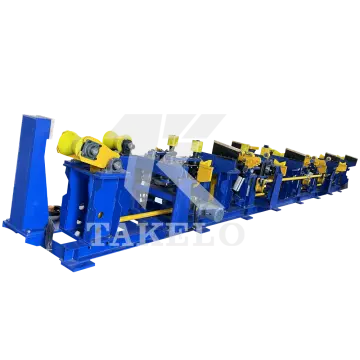

Navigating the world of non-magnetic drill collars can be a complex endeavor, especially for industry pioneers seeking to enhance their operational efficiency. To achieve excellence in this specialized field, it is essential to stay informed about the latest advancements in technology and equipment. One of the most critical aspects to consider is the innovation of manufacturing processes, where modern machinery plays a pivotal role in producing high-quality drill collars that meet rigorous industry standards. Investing in advanced equipment such as hydraulic make-up and Breakout Machines can significantly improve the reliability and performance of non-magnetic drill collars. These machines streamline the assembly process, reduce production downtime, and ensure consistent outcomes. Furthermore, threading machine conveyors enhance handling efficiency, allowing for a seamless transition from manufacturing to quality assurance. By incorporating cutting-edge marking and painting systems, manufacturers can also provide traceability and protection to their products, an essential factor for global procurement buyers who prioritize compliance and quality assurance. In conclusion, for those at the forefront of the non-magnetic drill collar sector, embracing innovation and technology from the factory floor to the field is paramount. Implementing expert strategies and investing in state-of-the-art equipment can pave the way for achieving factory-direct excellence. As the industry continues to evolve, staying adaptable and informed will ensure that pioneers can meet the demands of the global market while establishing their reputation for quality and reliability.

Expert Tips For Non-Mag Drill Collar Pioneers in the Field Factory-Direct Excellence

| Tip Number | Expert Tip | Application | Expected Outcome |

|---|---|---|---|

| 1 | Select the right weight for optimal performance. | Use a drilling simulator to determine required weight. | Improved drilling efficiency and reduced wear. |

| 2 | Monitor temperature during drilling. | Utilize thermal sensors near drilling area. | Reduced risk of tool failure and increased safety. |

| 3 | Regularly inspect and maintain equipment. | Establish a routine maintenance schedule. | Increased longevity of equipment and reduced downtime. |

| 4 | Choose non-magnetic materials where possible. | Identify and source alternative materials for drill collars. | Enhanced accuracy of magnetic survey tools. |

| 5 | Optimize drilling parameters based on formation. | Analyze formation data before drilling. | Maximized penetration rates and bit life. |

How To Pick The Right Non-Mag Drill Collar Leads the Global Market From Concept to Delivery

J

Joseph Evans

The product quality is fantastic! It’s rare to find such attention to detail.

10 May 2025

D

Daisy Bennett

The quality really speaks for itself. This is my go-to product now!

29 June 2025

S

Sophia Bell

The quality and performance are beyond my expectations. Truly remarkable!

04 June 2025

J

Julia Bell

Impressive quality! The performance is remarkable and consistent.

04 July 2025

E

Evelyn Cox

The after-sales service really puts them ahead of their competition.

08 May 2025

M

Mason Lee

Excellent craftsmanship and customer support! Truly impressive.

20 June 2025