Best Internal Pipe Coating Machines: Leading Suppliers & Factory Options

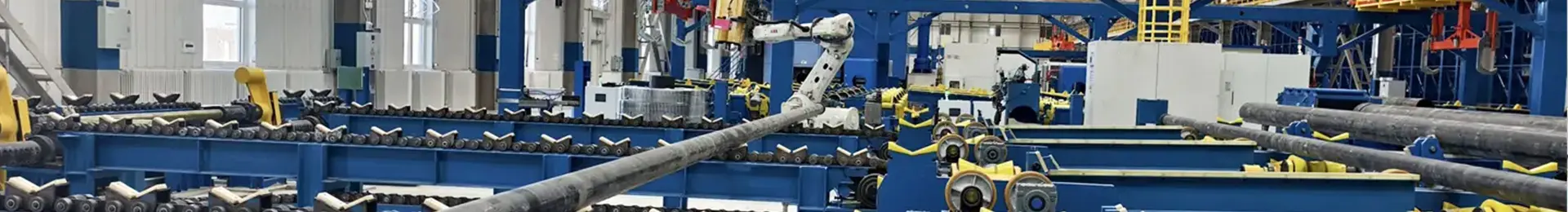

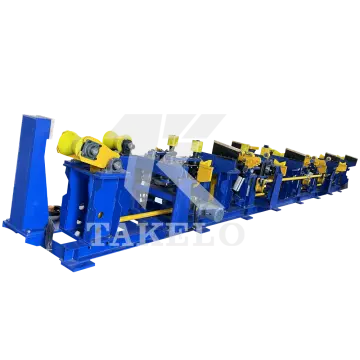

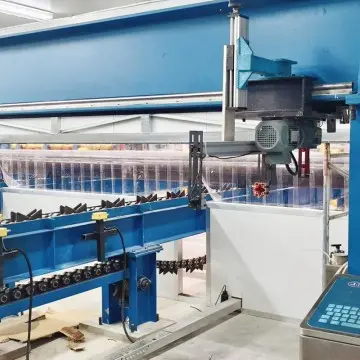

Our Internal Pipe Coating Machine is engineered for optimal efficiency and quality in the pipe coating process. As a leading manufacturer in China, we pride ourselves on delivering high-quality machinery that adheres to industry standards. Our machines are fully customizable to accommodate various pipe sizes and coating materials, ensuring they cater to the unique requirements of each project. At WUXI TAKELO MACHINERY CO., LTD., we leverage advanced technology and provide dependable support to our clients. With state-of-the-art production facilities, we ensure that every machine is durable and reliable. With years of industry experience, we are committed to enhancing your production capabilities and maximizing customer satisfaction.Tips & Tricks for Internal Pipe Coating Machine Winning in 2025 Now Trending

As the global market for internal pipe coating machines continues to evolve, staying ahead of trends is essential for procurement professionals seeking to optimize their operations. In 2025, the drive for efficiency and sustainability will redefine the capabilities required from these machines. One of the most crucial tips for success is to embrace advanced automation technologies. Integrating smart features into your coating machines can enhance precision, reduce material wastage, and streamline the overall process, making your procurement decisions not just cost-effective but also environmentally friendly. Another vital aspect to consider is the versatility of equipment. Machines that can handle multiple applications—such as swaging, hydraulic operations, and threading—offer significant advantages in terms of flexibility and productivity. Modernizing your facility with systems that provide seamless connectivity among different stages of the pipe coating process will further improve efficiency. Additionally, prioritize vendors that demonstrate a commitment to innovation, ensuring they have the capability to adapt and provide cutting-edge solutions as market demands change. Lastly, keep an eye on the latest painting and marking technologies that enhance the coating quality and durability, resulting in longer service life and reduced maintenance costs. By focusing on these trends and investing in the right technology now, procurement professionals can position themselves to excel in 2025 and beyond, ensuring they stay competitive in a rapidly changing landscape.

Tips & Tricks for Internal Pipe Coating Machine Winning in 2025 Now Trending

| Tip/Trick | Description | Expected Impact | Implementation Time |

|---|---|---|---|

| Regular Maintenance | Schedule monthly inspections and maintenance of coating machines. | Reduces downtime by 20%. | Ongoing |

| Operator Training | Invest in training programs for operators to enhance skills. | Improves efficiency by 30%. | 1 month |

| Advanced Coating Materials | Utilize new high-performance coating materials. | Enhances durability and lifespan of pipelines. | 2 months |

| Data Analytics | Implement data monitoring systems for real-time analysis. | Identifies potential issues before they escalate. | 3 months |

| Collaboration Tools | Use collaborative platforms for team communication and project management. | Enhances team productivity by 25%. | 1 month |

Key Methods For Internal Pipe Coating Machine Where Innovation Meets 2025 Ahead of the Curve

L

Linda Chen

Exceptional after-sales service! The support team was very responsive and knowledgeable.

14 June 2025

C

Charles Scott

The support staff really know their stuff. I felt confident in their guidance.

21 June 2025

E

Ella Robinson

Outstanding product! The quality is worth every cent!

20 May 2025

R

Ruby Edwards

The professionalism of the service staff was refreshing. They were a pleasure to work with.

09 June 2025

H

Hannah Green

Customer service was very professional, guiding me through my purchase.

25 May 2025

L

Lucas Ward

Extremely pleased with my purchase. The quality was fantastic!

23 May 2025