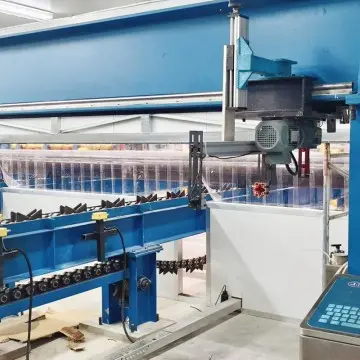

Hydraulic Make-up&Breakout Machine(Bucking Unit)

Features of machine

Our Digital Hydraulic Make-up&Breakout Unit integrates high-precision torque testing sensors to enable ±1% accuracy in spinner torque control. This digital feedback system dynamically adjusts hydraulic pressure to maintain specified torque values, eliminating over-tightening risks in make-up/breakout operations.

Equipped with high-torque spinner motors,the unit achieves:

1. 50% faster make-up/breakout cycles compared to conventional systems.

2. Continuous operation at 90% rated torque without performance degradation.

3. Automatic speed adjustment based on pipe diameter.

There are three models:

Model |

Pipe Size Range |

TKL-MB-1 |

60.3–177.8 mm (2⅜"–7") |

TKL-MB-2 |

177.8–340 mm (7"–13.38") |

TKL-MB-3 |

340–508 mm (13.38"–20") |

Torque Speciation:

Low speed: Max 100 kN·m

High speed: Max 50 kN·m

Product applications:

1. Workshop & Rig Operations: Automated makeup/breakout for all standard oilfield connections

2. Torque Precision: Digital load cells ensure ±1% torque accuracy, with automatic shutdown at target torque.

Engineering Innovations

1. Mark free surface: Jaws Technology for cabon steel material or 13Cr, super 13Cr, Nickel-based alloys,etc.

2.Top-Loading Mandrel Design: Enables direct horizontal loading of pipes and eliminates need for auxiliary pipe handling equpment.

3. High-Efficiency Torque System: Adopt Dual-speel operation-high speed&low speed, the Hydraulic accumulators ensure constant clamping force through entire torque cycle.

4. Wide-Clamping Range: Jaws for pipe size from 2 3/8”~20” and upside-down clamping cylinder design prevents pipe bending under high torque.