Top Drilling Component Suppliers & Manufacturers to Meet Your Needs

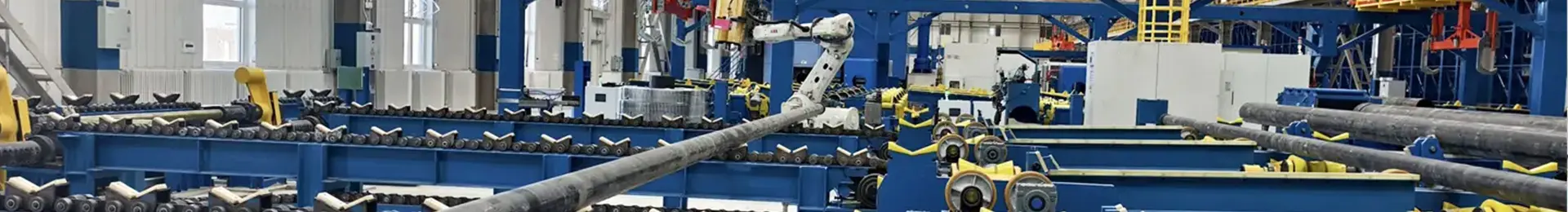

Are you in need of high-quality Drilling Components? Our products are meticulously engineered to meet the diverse needs of various industries, ensuring both durability and efficiency in every project. At WUXI TAKELO MACHINERY CO., LTD., we place a strong emphasis on excellence and customer satisfaction. With advanced technology integrated into our drilling components, they are perfect for a wide array of applications. Trust us for consistent quality and timely delivery, as we understand the significance of sourcing from a reliable manufacturer.

How-To Guide Drilling Components in 2025 Dominates

In the rapidly evolving landscape of drilling technology, staying ahead means embracing innovation and efficiency. As we look toward 2025, the demand for reliable and high-performance drilling components remains a top priority for global buyers. The industry is seeing a significant shift towards advanced equipment that not only meets labor demands but also enhances operational precision and productivity. Innovative solutions, such as swage machines and hydraulic make-up & Breakout Machines, play a critical role in optimizing drilling processes. These systems allow for seamless integration and handling, reducing downtime and improving effectiveness. Additionally, threading machine conveyors and specialized painting and marking systems ensure that components meet stringent quality standards while maintaining high throughput. As technology continues to advance, the incorporation of automation and smart technology will further enhance efficiency, driving cost savings for procurement managers worldwide. As procurement professionals gear up for 2025, the focus will shift towards partnerships that prioritize innovation and reliability in drilling components. Companies that prioritize research and development will lead the way, equipping buyers with the tools necessary to navigate the complexities of drilling operations effectively. Embracing these advancements is no longer an option but a necessity for those looking to dominate in the competitive drilling landscape.

How-To Guide Drilling Components in 2025 Dominates

| Component Type | Material | Diameter (mm) | Weight (kg) | Production Year | Application |

|---|---|---|---|---|---|

| Drill Bit | Carbide | 32 | 1.5 | 2025 | Oil & Gas |

| Drill Pipe | Steel | 127 | 50.0 | 2025 | Mining |

| Casing | PVC | 100 | 20.0 | 2025 | Water Well |

| Core Barrel | Aluminum | 76 | 15.0 | 2025 | Geological |

| Drill Collars | Heavy Steel | 50 | 30.0 | 2025 | Petroleum |

Best Way To Choose Drilling Components Outperforms the Competition Global Reach

R

Robert Patel

I was impressed with the professionalism of the service staff. They resolved my issue promptly!

04 June 2025

S

Sophie Martinez

A solid purchase! The quality is consistent and reliable.

19 June 2025

L

Lily Parker

I couldn’t be happier with my purchase. Excellent quality and support!

30 June 2025

V

Victoria Foster

Fantastic quality! The follow-up service was also on point.

08 July 2025

C

Charlotte Bennett

Amazing craftsmanship! The support team was attentive and very helpful.

16 June 2025

G

Grace Morris

Efficient and friendly support. They really made the process easy for me!

15 June 2025