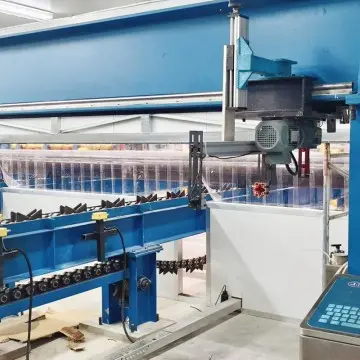

Casing&Tubing Swaging machine(Reduce&expand pipe size)

Features of machine

1.Sustained Precision Engineering:Ensure the accurate thickness and low bend data to make the perfect workpiece.

2. Efficient replacement of pipe size:Operator can replace the dies for different pipe sizes quickly.

3.Easy maintenance: The design enable quick, single-person maintenance, save much time for manufatuers.

4.Prior material and quality ensure long-time usage life.

5.Market Leadership: 98% Segment Dominance, most of leading pipe manufactures are using our swaing machine. Such as CNPC, CNOOC, SINOPEC, CTA, Vallourec, Henggang, AMCO, TPCO, BAOSTEEL, Changbao Steel Pipe,etc.

There are three models:

Model |

TKL-SW-180 |

TKL-SW-340 |

TKL-SW-508 |

Pipe size |

2 3/8”~7” |

7”~13 3/8" |

13 3/8”~20” |

Pipe steel grade |

H40、 J55 、M65、 N80-1、L80-1、L80-13Cr、C90、T95、R95、P110、C110、 Q125、BG-140V、BG-150V、BG155V,etc |

||

Pipe wallthickness/tolerance |

4.83~16mm/-12.5%t ~15%t |

4.83~30mm/-12.5%t ~15%t |

4.83~30mm/-12.5%t ~15%t |

Pipe length |

0.6~13m |

0.6~13m |

0.6~13m |

Max pipe weight |

1000kgs |

3000kgs |

4500kgs |

Pipe OD tolerance |

±1% |

±1% |

±1% |

Pipe Bend |

Pipe end ≤4 mm/1.5m Pipe body≤0.2%L |

||

Pipe Ovality |

≤0.8%D |

||

Standard equipments: Including hydrualic power unit with prior quality, Main machine, Frame stand cabinet, Electric panel control(PLC), 2 sets of dies.

Optional auxiliary:

1.We can also design and make conveyors for in-feed and out-feed conveyors for the machine to meet customers’ operation requirement at site.

2.More size for dies: from size 2 3/8”~20”, customers can choose more size of dies.