Top Blowout Preventer Suppliers and Factories You Need to Know About

As an expert in drilling safety, I recognize the essential function of blowout preventers in safeguarding operations. Our Blowout Preventer Function offers unparalleled control during high-pressure scenarios, allowing you to operate with certainty. We source our equipment from trusted Chinese manufacturers known for their durability and performance. At WUXI TAKELO MACHINERY CO., LTD., we emphasize quality and precision, ensuring our products adhere to international standards. Our dedication to excellence provides you with reliable blowout preventers that enhance your operational capabilities. By partnering with us, you're investing in advanced technology that propels your business forward, fulfilling your operational demands and elevating production standards in a competitive landscape.

Key Methods For Blowout Preventer Function Where Innovation Meets 2025 Leads the Global Market

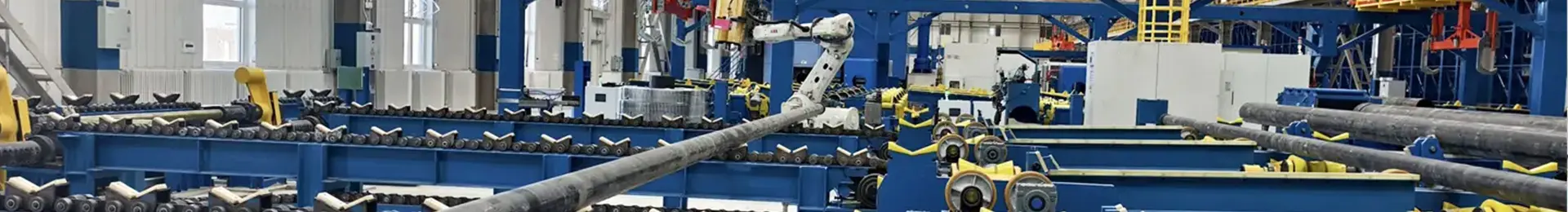

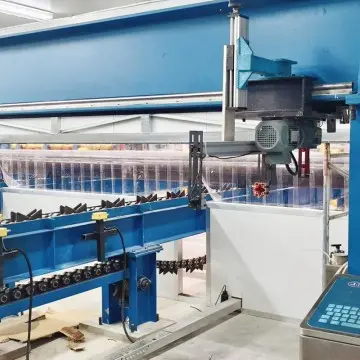

In the ever-evolving Oil And Gas Industry, the blowout preventer (BOP) serves as a critical line of defense against uncontrolled well flow, ensuring not only operational safety but also regulatory compliance. As we approach 2025, innovative advancements in BOP technology are set to reshape the global market landscape. Our commitment to research and development has led to the creation of cutting-edge equipment that enhances the efficiency and reliability of blowout preventers. From precision-engineered swage machines to hydraulic make-up and breakout machines, we empower operators to manage their workflows seamlessly and mitigate risks associated with well control. The integration of sophisticated handling systems and automated painting and marking solutions streamlines maintenance processes and reduces downtime, enabling operators to focus on productivity without sacrificing safety. By leveraging these innovative tools, companies can ensure that their BOPs are always in peak condition, ready to perform when it matters most. As industry demands increase and safety regulations tighten, the adoption of advanced BOP technologies will be essential for procurement professionals seeking reliable partners in a competitive global market. As we stride towards 2025, the collaboration between innovative equipment manufacturers and global procurement teams is pivotal. Our state-of-the-art solutions not only address current market needs but are also designed with the future in mind, ensuring adaptability in a rapidly changing landscape. Embracing these advancements will position companies at the forefront of safety and efficiency, ultimately leading to sustained growth and success in the global oil and gas sector.

Key Methods For Blowout Preventer Function Where Innovation Meets 2025 Leads the Global Market

| Method | Description | Expected Outcome | Implementation Timeline | Market Impact |

|---|---|---|---|---|

| Automated Control Systems | Integration of AI and machine learning for real-time monitoring | Improved safety and reduced human error | 2025 | Projected growth in safety compliance market |

| Enhanced Sealing Technology | Development of new materials for better sealing | Increased reliability under high-pressure conditions | 2024 | Higher demand for durable blowout preventers |

| Remote Monitoring Tools | Use of IoT devices for continuous data collection | Early detection of potential failures | 2023 | Impact on operational efficiency and cost reduction |

| Training and Simulation Programs | Virtual reality training for emergency response | Enhanced preparedness and response times | 2025 | Increased workforce competency and safety culture |

| Regulatory Technology (RegTech) | Tools for compliance monitoring and reporting | Streamlined regulatory processes | 2024 | Greater adherence to safety regulations |

Best Methods To Blowout Preventer Function Ahead of the Curve Factory

J

James Thompson

The product quality exceeded my expectations. The attention to detail is truly commendable!

07 July 2025

K

Kevin White

Customer service was a delight. The staff was well-trained and courteous.

18 June 2025

M

Michelle Anderson

Fantastic quality! The attention to detail is evident in every aspect of the product.

26 June 2025

A

Ava Nelson

The durability of this product speaks volumes. A great investment for my business!

13 June 2025

J

Jordan Bennett

High-quality product that exceeded my expectations in every way!

29 June 2025

H

Hazel Martinez

Quick and efficient service! The staff’s expertise made a big difference.

02 June 2025