Top Blowout Preventers (BOPs) from Leading Manufacturers | Reliable Factory Solutions

Reliable blowout preventers (BOP) are essential for safe drilling operations, and selecting a trusted manufacturer is crucial. With extensive industry experience, we proudly deliver high-quality Blowout Preventer Bop systems from our advanced facility in China. Our products adhere to stringent safety standards and are designed for optimal performance in demanding drilling environments. At WUXI TAKELO MACHINERY CO., LTD., we focus on understanding your specific requirements, offering tailored solutions to boost operational efficiency. Partner with us for exceptional quality and innovation, backed by dedicated service and support throughout your experience. Elevate your drilling operations with our cutting-edge Blowout Preventer BOP technology!

Top-Rated Blowout Preventer Bop Now Trending Service

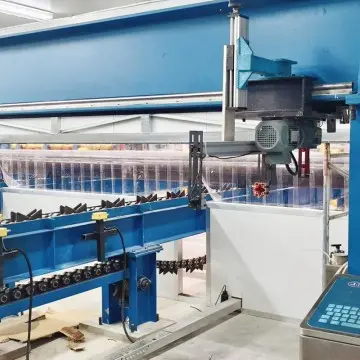

In the ever-evolving landscape of industrial equipment, the importance of reliable safety mechanisms cannot be overstated. The rise of top-rated blowout preventers (BOPs) in trending services reflects a crucial adaptation to modern operational challenges. These essential devices are designed to prevent uncontrolled oil and gas flows, ensuring the safety of workers and the environment. As industries increasingly recognize the value of cutting-edge BOP systems, the demand for innovative solutions grows, highlighting the need for manufacturers that prioritize advanced technology and reliability. Our focus on innovation has led to the development of a comprehensive range of equipment tailored to enhance efficiency and safety in various industries. From swage machines that streamline production processes to hydraulic make-up and Breakout Machines that provide unmatched performance, our products are engineered to meet the demands of today's market. Moreover, our threading machine conveyors and painting systems offer seamless handling and finishing, ensuring that each component meets stringent quality standards. By investing in advanced technology, businesses can not only improve operational safety but also boost productivity and profitability in an increasingly competitive global landscape. As we witness the escalating interest in top-rated BOPs and related services, procurement professionals are encouraged to consider innovative suppliers who focus on integrating technology with practicality. The synergy of advanced machinery equipment and robust safety features forms the cornerstone of future-proof operations. Choosing the right partner can significantly impact both operational efficiency and safety outcomes, ultimately leading to sustainable growth in the demanding world of energy and industrial production.

Top-Rated Blowout Preventer Bop Now Trending Service

| Model | Pressure Rating (psi) | Weight (lbs) | Dimensions (inches) | Material | Applications |

|---|---|---|---|---|---|

| BOP-1000 | 5000 | 1200 | 30 x 30 x 50 | Alloy Steel | Oil & Gas, Well Control |

| BOP-2000 | 7500 | 1500 | 35 x 35 x 55 | Stainless Steel | Deepwater Drilling |

| BOP-3000 | 10000 | 1800 | 40 x 40 x 60 | Carbon Steel | Land-Based Drilling |

| BOP-4000 | 12000 | 2000 | 45 x 45 x 65 | High Tensile Steel | Subsea Operations |

| BOP-5000 | 15000 | 2200 | 50 x 50 x 70 | Titanium Alloy | Critical Well Control |

Methods To choose Blowout Preventer Bop Where Innovation Meets 2025 More Than a Supplier - A Partner

D

David Mitchell

I appreciate the thorough follow-up from the customer service team.

02 July 2025

B

Brian King

Amazing after-sales service. They really care about their customers!

15 June 2025

H

Hannah Green

Customer service was very professional, guiding me through my purchase.

25 May 2025

S

Samantha Cooper

The level of service I received was outstanding. Very dedicated team!

07 June 2025

D

David Hughes

Product is well-constructed and functions perfectly on every level.

23 June 2025

L

Luna Reed

Great product with superb quality! They really understand their market.

15 June 2025