Top-Quality Blow Out Preventer Parts from Trusted Manufacturers - Quality Assured

High-quality Blow Out Preventer Parts are essential for the oil and gas industry, ensuring safety and efficiency in drilling operations. At WUXI TAKELO MACHINERY CO., LTD., we manufacture a wide range of durable and reliable components that meet rigorous industry standards. Our commitment to excellence and customer satisfaction is unmatched. With advanced technology and robust materials, our parts are designed to perform reliably under pressure. Whether you require a single component or bulk quantities, we are equipped to meet your needs promptly. Contact us today to learn how we can support your business with our premium Blow Out Preventer Parts.Best Practices For Blow Out Preventer Parts Now Trending Custom Solutions,

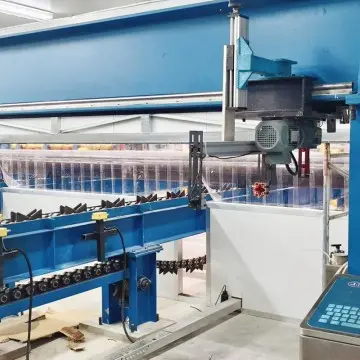

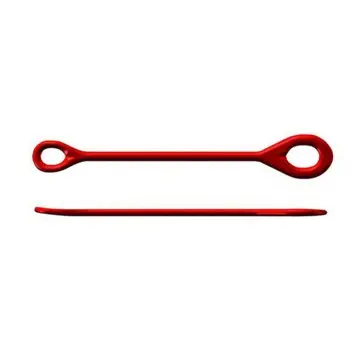

In the ever-evolving landscape of oil and gas extraction, Blow Out Preventer (BOP) parts play a crucial role in ensuring safety and efficiency. As industries increasingly prioritize custom solutions tailored to specific operational needs, understanding the best practices for sourcing these vital components has become essential. Global procurement professionals are recognizing the importance of innovation in the design and manufacturing of BOP parts, as bespoke solutions can significantly enhance performance and extend the lifespan of the equipment. Customization is not merely an option but a necessity for meeting diverse operational demands across various geographical locations. This trend highlights the need for collaborative relationships between suppliers and purchasers to develop equipment that meets unique specifications while adhering to rigorous safety standards. By leveraging cutting-edge technologies, manufacturers are able to provide swage machines, hydraulic make-up and Breakout Machines, and tailor-made handling systems that ensure smoother operations and increase reliability in challenging environments. Moreover, procurement strategies should encompass continuous evaluation of the latest advancements in BOP technology and manufacturing processes. Enhanced features such as improved threading capabilities and advanced painting and marking systems not only contribute to the longevity of the components but also facilitate easier tracking and maintenance. By staying ahead of emerging trends and embracing innovative solutions, companies can optimize their operations and ensure that their BOP systems remain resilient and effective in preventing blowouts, thereby safeguarding personnel and investments in the field.

Best Practices For Blow Out Preventer Parts Now Trending Custom Solutions

| Part Name | Material | Dimensions (inches) | Weight (lbs) | Custom Features |

|---|---|---|---|---|

| Seal Element | Nitrile Rubber | 5 x 3 x 1 | 0.5 | High Temperature Resistance |

| Control Valve | Stainless Steel | 8 x 4 x 3 | 3.2 | Remote Operation Capability |

| BOP Connector | Carbon Steel | 6 x 2 x 2 | 2.0 | Anti-Corrosion Coating |

| Hydraulic Cylinder | Aluminum Alloy | 10 x 5 x 5 | 4.5 | Lightweight Design |

| Actuator | Composite Material | 7 x 3 x 1 | 1.0 | Electromechanical Integration |

Practical Strategies for Blow Out Preventer Parts Ahead of the Curve Industry Giant

L

Linda Chen

Exceptional after-sales service! The support team was very responsive and knowledgeable.

14 June 2025

R

Robert Patel

I was impressed with the professionalism of the service staff. They resolved my issue promptly!

04 June 2025

N

Nora Collins

The durability of this product is impressive. Great value for the price!

18 May 2025

C

Clara Reed

This product is a game changer! Quality is impressive and the service is fantastic.

25 May 2025

I

Isaac Reed

The quality and craftsmanship are unmatched. 10/10!

27 June 2025

D

Daniel Morales

Quality that speaks for itself! I’m very impressed overall.

26 June 2025