-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

As the oil and gas industry evolves, the innovations and trends surrounding drill collars are becoming increasingly significant. In 2025, professionals are poised to witness transformative changes in drill collar technology that are aimed at enhancing efficiency and safety in drilling operations. Renowned industry expert Dr. Emily Carter, a leading figure in drilling engineering, remarks, "The future of drill collars is not just about strength and durability; it's about integrating smart technologies that can revolutionize how we approach drilling challenges."

In this dynamic landscape, various advancements are anticipated, from the implementation of advanced materials to the incorporation of real-time data analytics that allow for more informed decision-making. The shift towards smarter drill collars represents a broader trend within the drilling industry, focusing on optimizing performance while minimizing environmental impact. Understanding these trends is crucial for professionals aiming to stay competitive in a rapidly changing market.

As we delve into the top drill collar trends and innovations for 2025, it is essential to recognize the growing emphasis on both operational efficiency and the adoption of cutting-edge technologies. This exploration will provide valuable insights into how drill collars are evolving and what that means for the future of drilling operations as a whole.

In 2025, the evolution of drill collars will be significantly influenced by the introduction of emerging materials designed to enhance performance in diverse drilling environments. One of the most promising materials is carbon fiber-reinforced polymer (CFRP), which boasts an impressive strength-to-weight ratio. This innovation allows for lighter drill collars that can withstand high pressures and temperatures, ultimately improving efficiency and reducing wear over extended drilling operations.

Another notable advancement is the use of advanced composites that incorporate nanomaterials. These composites are engineered to enhance toughness and fatigue resistance, making drill collars more durable and reliable in abrasive conditions. The integration of smart materials, which can adapt to varying environmental factors, is also gaining traction; these materials respond to stress changes during drilling, providing real-time feedback and minimizing failures. As these innovative materials are adopted, drill collar performance will see substantial improvements, paving the way for more efficient and cost-effective drilling solutions in the industry.

The advancements in drill collar design are pivotal in enhancing rig efficiency, particularly as the industry grapples with the push for reduced downtime and increased performance. The integration of advanced materials, such as lightweight composites, allows for improved load management while maintaining structural integrity. These materials not only minimize wear and tear but also enhance resistance to environmental factors, extending the lifespan of drill collars significantly.

Tips for Choosing the Right Drill Collar:

When selecting a drill collar, consider the specific drilling conditions and the type of formation being encountered. Choosing a collar that offers optimal balance between weight and strength will greatly influence the drilling process. Additionally, stay updated on innovations in coating technologies that can provide better protection against corrosion and wear.

Moreover, incorporating advanced computational modeling in the design phase can lead to drill collars that are finely tuned for high-efficiency performance. The ability to simulate stress and strain during the design process ensures that collars withstand extreme conditions while maximizing penetration rates. Embracing these innovations not only streamlines operations but also contributes to a more sustainable approach in drilling practices.

The integration of smart technologies in drill collar operations is set to reshape the landscape of the drilling industry by 2025. As companies increasingly adopt artificial intelligence (AI) strategies, autonomous agents are being integrated to optimize drilling processes. According to recent industry reports, employing AI can lead to a decrease in operational costs by up to 30% while simultaneously reducing emissions by 15%. This technology not only streamlines decision-making but also enhances safety by predicting and mitigating risks in real-time.

Moreover, innovative clean energy technologies are revolutionizing traditional drilling operations. For instance, incorporating solar power systems into drilling activities can considerably lower energy expenses while minimizing the carbon footprint. Research indicates that these advancements could reduce overall emissions by nearly 25% in drilling operations by the year 2025. The convergence of information technology (IT) and operational technology (OT) is also crucial; as firms embrace this integration, they can achieve a unified security framework essential for safety and compliance in an increasingly digital environment. This synergy supports the transition to Industry 4.0, positioning companies to thrive in a rapidly evolving energy market.

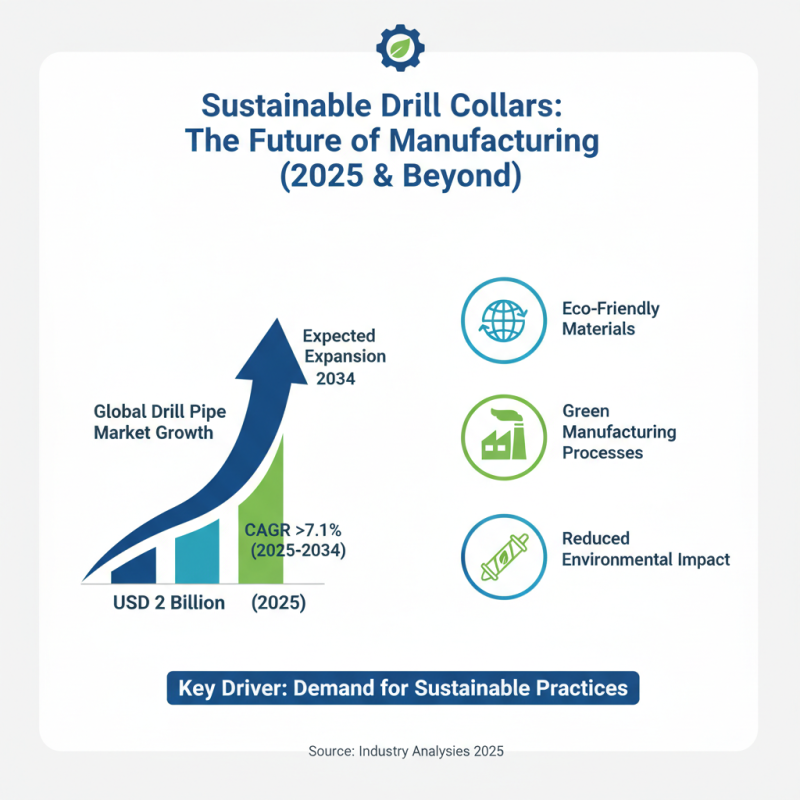

As we look towards 2025, sustainability is poised to significantly shape the manufacturing of drill collars in the oil and gas sector. Industry analyses indicate that the global drill pipe market, currently valued at USD 2 billion, is expected to expand at a CAGR of over 7.1% from 2025 to 2034. This growth is driven by a growing demand for sustainable practices and materials within manufacturing processes, highlighting the necessity for environmentally-friendly innovations in drill collar production.

Additionally, the impact of government support for sustainable technologies cannot be overlooked. The seamless pipe market is expected to create lucrative opportunities, spurred by various government initiatives aiming to enhance sustainable industrial practices. Reports suggest that the global horizontal directional drilling market could reach USD 43.59 billion by 2032, growing at a CAGR of 11.75% from 2025. This trend indicates a strong shift towards techniques that reduce environmental impact while improving efficiency—a critical requirement for drill collar manufacturers moving forward.

In the evolving landscape of the oil and gas industry, drill collar innovations are poised to play a crucial role in enhancing operational efficiency and safety. By 2025, advancements in materials and technology are expected to pave the way for lighter, stronger, and more resilient drill collars. These innovations will not only improve drilling performance but also reduce the environmental impact of drilling operations. The integration of artificial intelligence and real-time data analytics into drill collar design and usage will enable companies to optimize drilling parameters dynamically, leading to significant cost savings and reduced downtime.

Moreover, as the global oilfield integrity management market is projected to grow from $15.61 billion in 2025 to $26.18 billion by 2032 at a CAGR of 7.67%, the demand for innovative drilling solutions is likely to surge. Enhanced drill collar technologies will be pivotal in ensuring the integrity and longevity of drilling operations, mitigating risks associated with equipment failure. The anticipated shift towards sustainable practices within the industry will further accelerate the adoption of innovative drill collar designs, emphasizing the need for materials that are both efficient and environmentally friendly. As we approach 2025, the synergy between technological advancements and industry needs will be fundamental in shaping the future of drill collar innovations.