Automatic Pipe Handling System/Conveyor for Casing&Tubing&Drill pipe

Key Capabilities

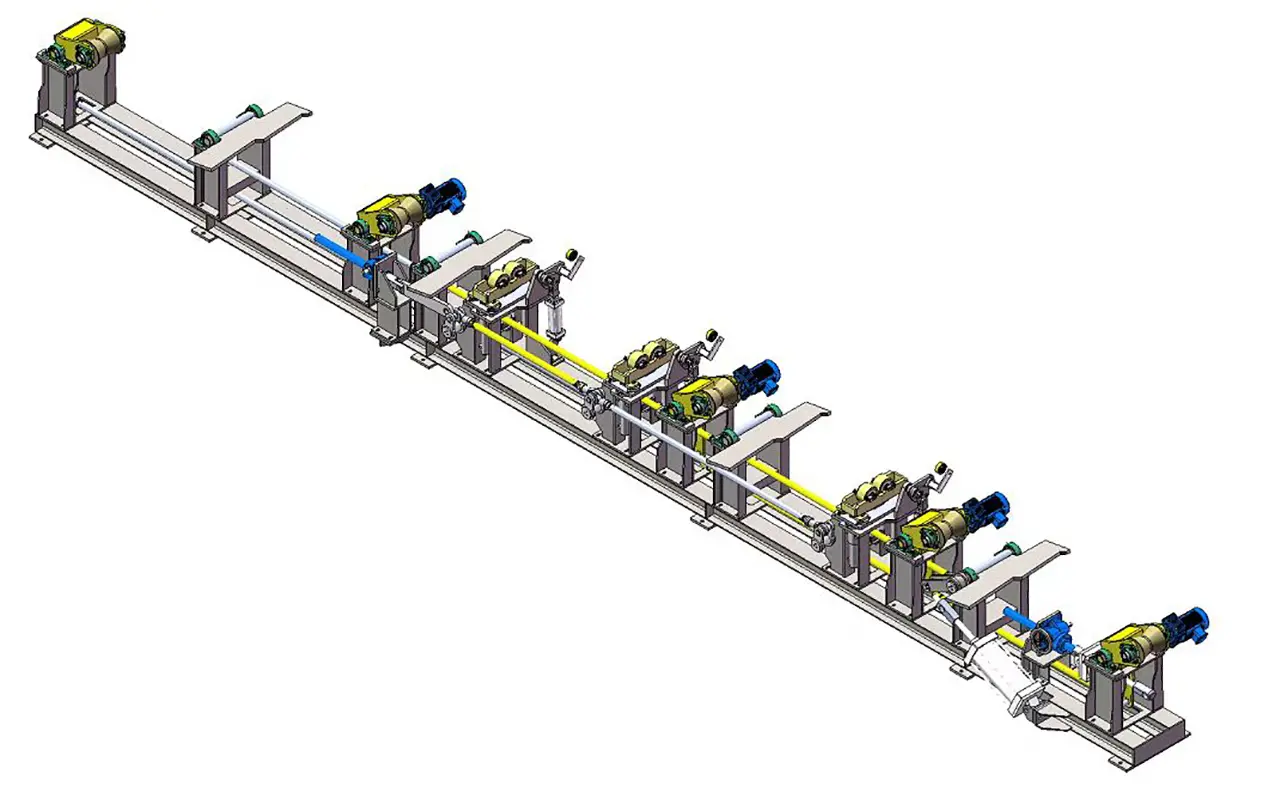

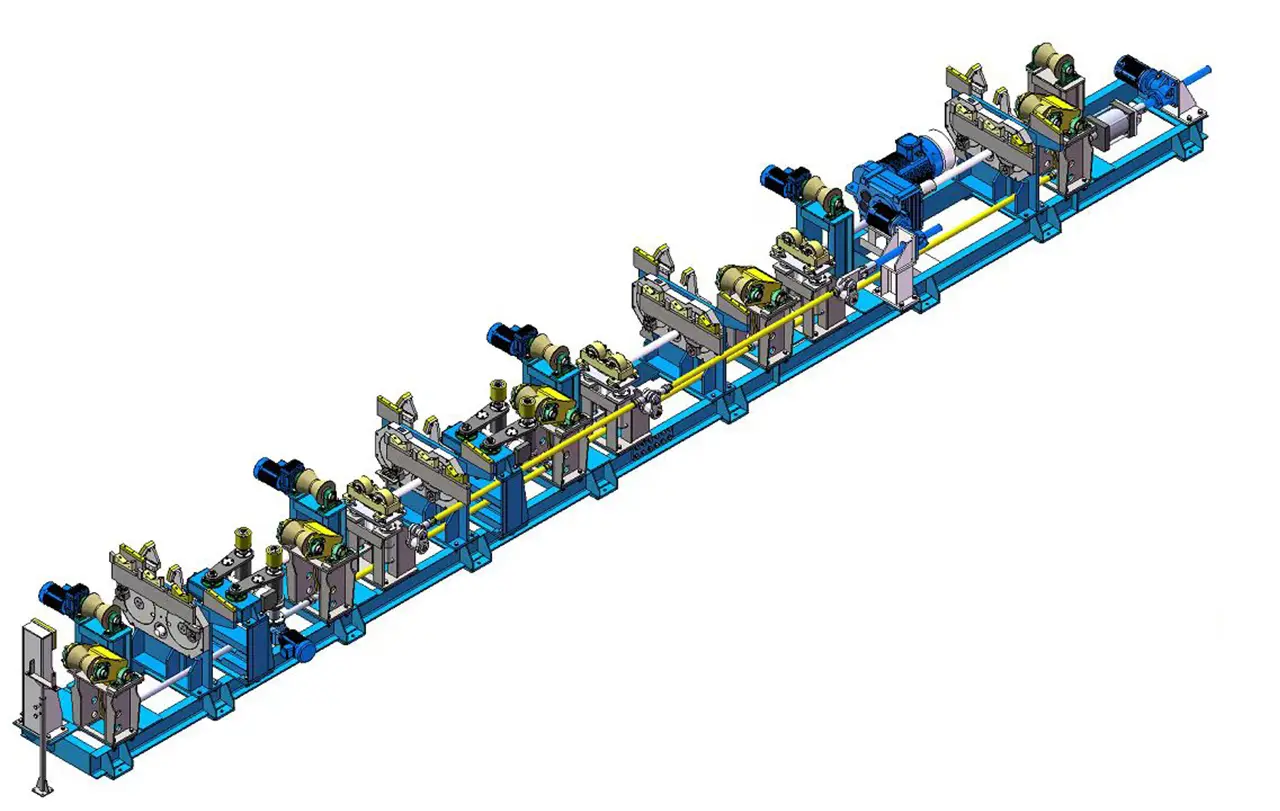

We can create highly optimized pipe handling equipment layouts, taking into account factors such as the specific manufacturing processes of our clients, the available workshop space, and future scalability requirements. Whether it's a large - scale manufacturing facility or a smaller, specialized operation, we craft bespoke designs that are tailored to the unique needs of each company.

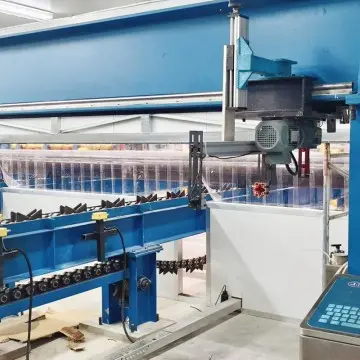

We operate state - of - the - art production facilities in Wuxi, equipped with high - tech machinery and automated assembly lines. These enable us to produce high - quality pipe handling equipment with tight tolerances and consistent performance. From the initial raw material selection, where we source only the highest - grade steel and other materials, to the final product assembly, every step is subject to rigorous quality control checks.

Assembly and installation are carried out by our team of trained professionals. We understand that a seamless transition from the manufacturing floor to the client's facility is crucial. Our installers work closely with clients, providing on - site support and training to ensure that the equipment is integrated smoothly into their existing operations. We also offer post - installation services, including equipment calibration and fine - tuning, to guarantee optimal performance.

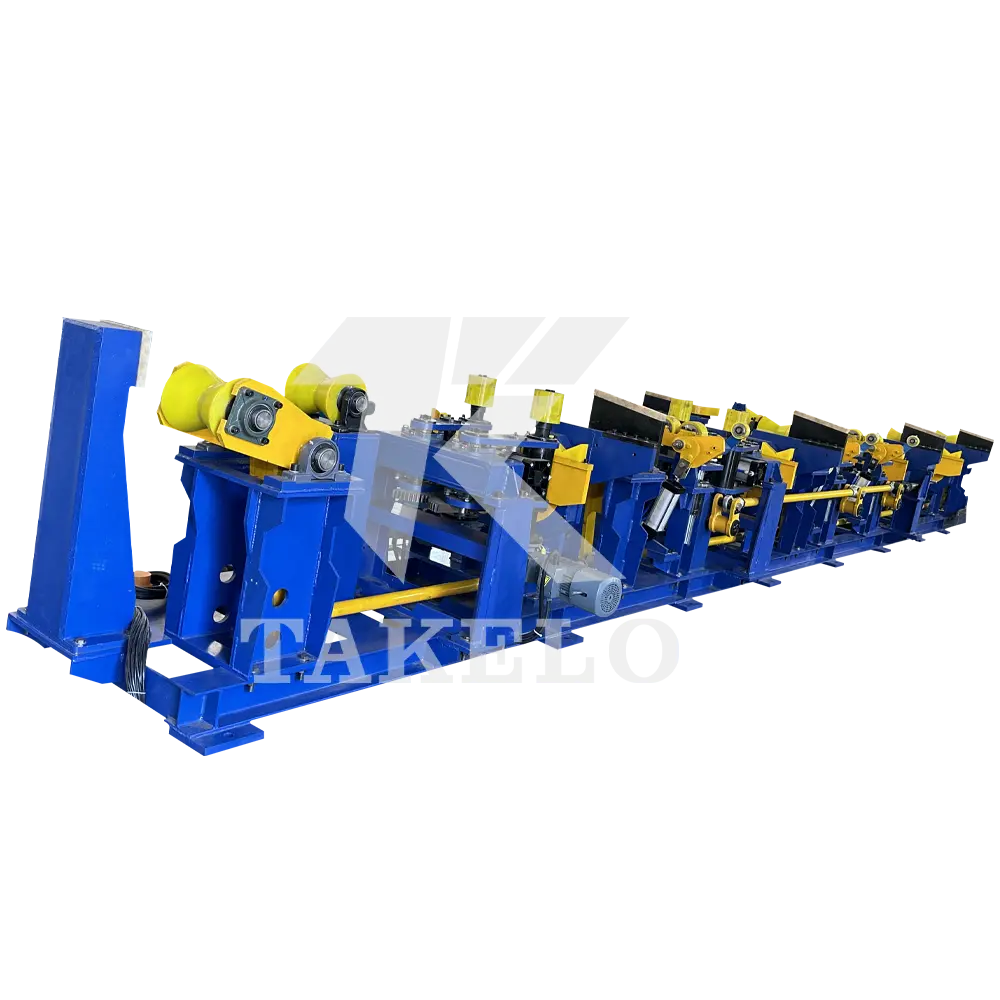

WuXi TAKELO has the skills and resources to handle all sizes and materials of casing, tubing, and drill pipe handling equipment. Engineered with durability in mind, our systems and equipment are tested to withstand the harshest operating conditions.

Our Pipe handling system/Conveyor are available for below.

There are three models:

Pipe Size |

Type |

60.3~340mm |

Flap type&Walking beam type |