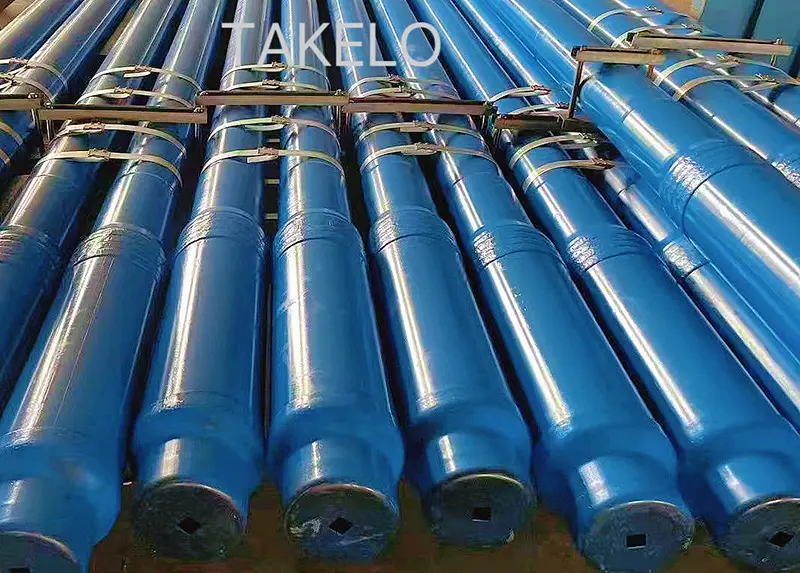

API Spec 7-1 Heavy weight drill pipe

Feachtures

With extensive field applications in both onshore and offshore drilling, TAKELO HWDP has repeatedly demonstrated lower failure rates and extended run life, making it a trusted choice for operators seeking durability and reduced non-productive time (NPT).

Product Specification

|

Size (in) |

(In) |

I.D. (in) |

Tool Joint O.D. (in) |

Tool Joint ID. (in) |

Connection |

Max. Elevator Diameter(in) |

Central upset Dia.(in) |

Min. Drift Dia. Size(in) |

3 1/2 |

3 1/2 |

2 1/4 |

4 3/4 |

2 1/4 |

NC38 |

3 7/8 |

4 |

2 |

2 1/16 |

(4 7/8,5) |

2 1/16 |

1 13/16 |

|||||

4 |

4 |

2 1/2 |

5 1/4 |

2 1/2 |

NC40 |

4 3/16 |

4 1/2 |

2 1/4 |

2 9/16 |

2 9/16 |

2 5/16 |

||||||

4 1/2 |

4 1/2 |

2 11/16 |

6 1/4 |

2 11/16 |

NC46 |

4 11/16 |

5 |

2 7/16 |

2 3/4 |

2 3/4 |

2 1/2 |

||||||

2 13/16 |

2 13/16 |

2 9/16 |

||||||

5 |

5 |

3 |

6 5/8 |

3 |

NC50 |

5 1/8 |

5 1/2 |

2 3/4 |

5 1/2 |

5 1/2 |

3 1/4 |

(7 1/4,7 1/2) |

3 1/4 |

5 1/2 FH |

5 11/16 |

6 |

3 |

3 3/8 |

3 3/8 |

3 1/8 |

||||||

3 7/8 |

3 7/8 |

3 5/8 |

||||||

4 |

4 |

3 3/4 |

||||||

6 5/8 |

6 5/8 |

4 |

8 (8 1/4,8 1/2) |

4 |

6 5/8 FH |

6 15/16 |

7 1/8 |

3 3/4 |

4 1/2 |

4 1/2 |

4 1/4 |

||||||

5 |

4 3/4 |