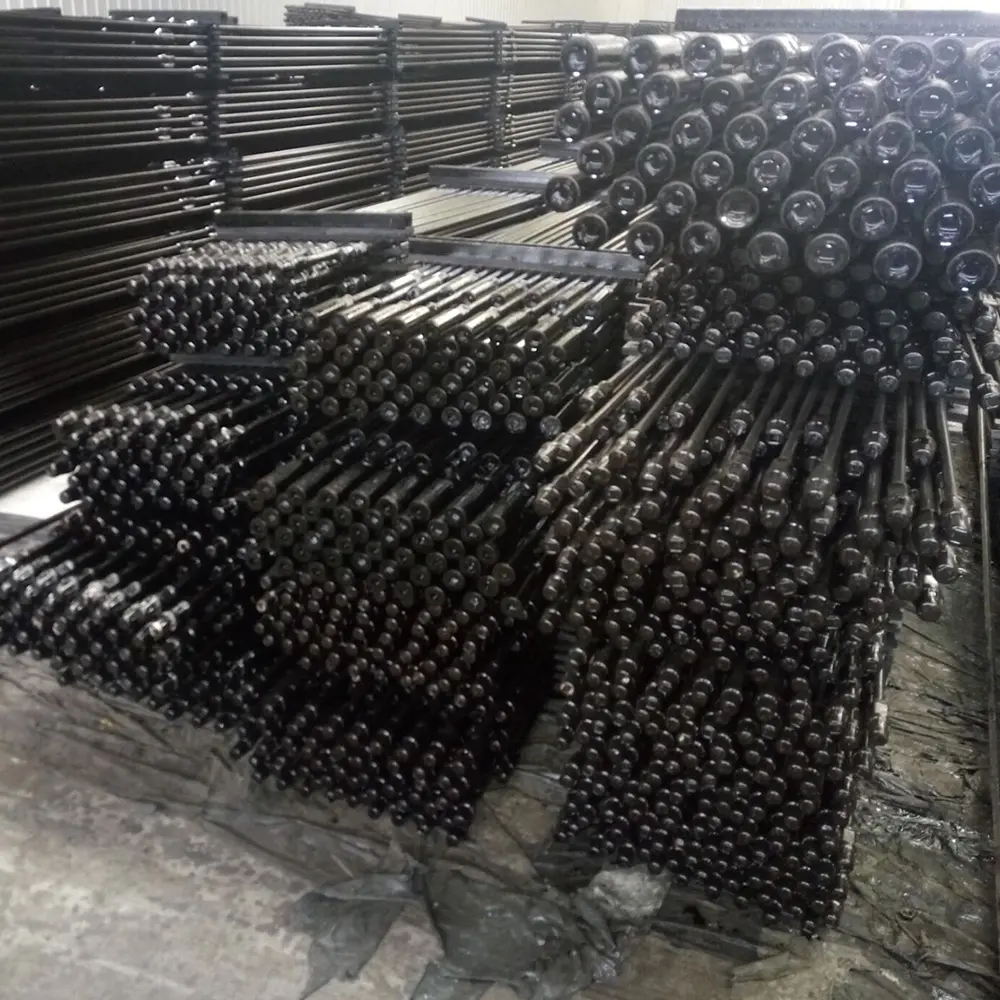

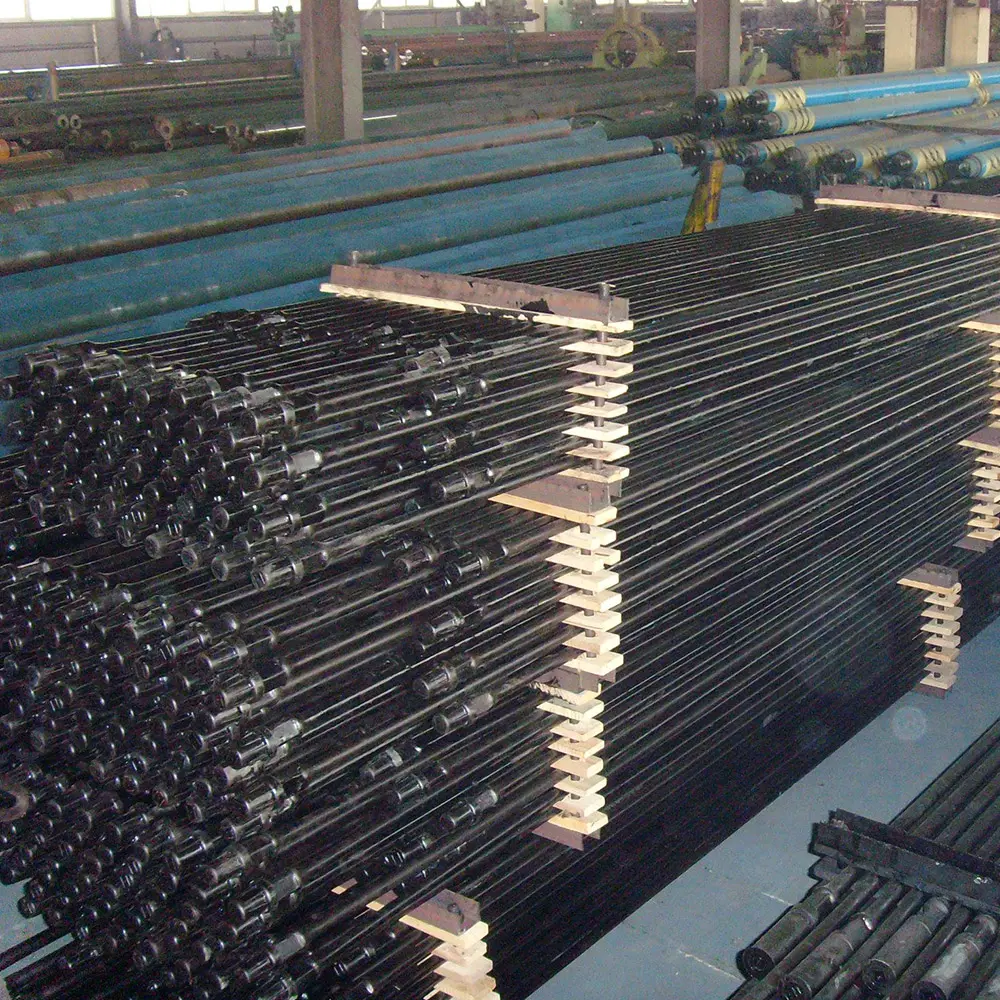

API spec 11B Sucker Rod Manufacturing

Key applications include

Sucker Rod&Pony Rod Specification

|

Size |

Thread D. |

Length |

Outside Diameter of Pin Shoulder |

Length of Thread |

Length of Wrench Square |

Width of Wrench Square |

|

(in) |

(in) |

(ft) |

(mm) |

(mm) |

(mm) |

(mm) |

|

5/8 |

15/16 |

2 4 6 8 10 25 30 |

31.8 |

31.75 |

≥ 31.8 |

22.2 |

|

3/4 |

11/16 |

38.1 |

36.5 |

25.4 |

||

|

7/8 |

1 3/16 |

41.3 |

41.28 |

|||

|

1/1 |

1 3/8 |

50.8 |

47.63 |

≥ 38.1 |

33.3 |

|

|

1 1/8 |

1 9/16 |

57.2 |

53.98 |

≥ 41.3 |

38.1 |

|

|

Grade |

Yield Strength |

Tensile Strength Rm (Mpa) |

Percentage Elongation A |

Contraction Percentage of Area Z (%) |

Impact Toughness |

|

|

Rel (Mpa) |

(%) |

a(3/cm2) |

||||

|

C |

≥ 414 |

620-793 |

≥ 12 |

≥ 55 |

≥ 70 |

|

|

D |

≥ 620 |

794-965 |

≥ 10 |

≥ 505 |

≥ 58.85 |

|

|

K |

≥ 414 |

620-793 |

≥ 12 |

≥ 55 |

≥ 70 |

Polished rod Specification

|

Size |

Rod D. |

Length |

Thread D. (in) |

Thread Length (mm) |

Small Diameter Taper of Thread |

||

|

(in) |

(mm) |

(ft) |

|||||

|

1 |

25.4 |

30 25 24 16 |

15/16 |

28.58 |

9° |

||

|

1 Upset |

15/16 |

1 1/16 |

31.75 |

36.5 |

|||

|

1/8 |

28.6 |

15/16 |

1 1/16 |

34.93 |

|||

|

1-1/8 Upset |

1 3/16 |

1 3/8 |

41.28 |

47.63 |

|||

|

1 1/4 |

31.8 |

1 3/16 |

34.93 |

||||

|

1-1/4 Upset |

1 3/8 |

1 9/16 |

47.63 |

53.98 |

|||

|

1 1/2 |

38.1 |

1 3/8 |

44.45 |

||||

|

Grade |

Yield Strength Rel (Mpa) |

Tensile Strength Rm (Mpa) |

Percentage Elongation A (%) |

Contraction Percentage of Area Z (%) |

Impact Toughness ak(J/cm2) |

||

|

1 |

≥ 414 |

620-827 |

≥ 12 |

≥ 55 |

≥ 70 |

||

|

2 |

General |

≥ 586 |

655-1102 |

≥ 10 |

≥ 50 |

≥ 58.8 |

|

|

Anti-corrosion |

≥ 414 |

≥ 12 |

≥ 55 |

≥ 70 |

|||