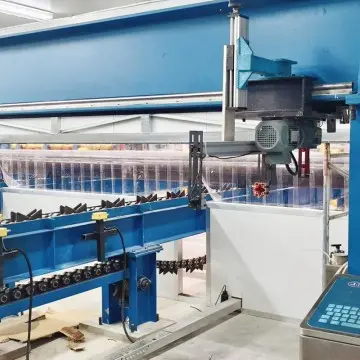

API Certified Sucker Rod Pump Manufacturing

The pumps integrate

Sucker Rod Pump Specification

|

Type |

Code |

O.D (mm) |

PlungerLength (m) |

Barrel Length (m) |

Outer Tube O.D (mm) |

Sucker Rod O.D (mm) |

Extended Joint Length (m) |

|

Tubing Pump |

20/25-106TH |

28.5 |

0.6~2.1 |

3.3~ 9.5 |

60.3~ 73.0 |

15.9~ 19.1 |

0.6~0.9 |

|

20/25-125TH |

31.8 |

0.6~2.1 |

3.3~ 9.5 |

60.3~ 73.0 |

15.9~ 19.1 |

0.6~0.9 |

|

|

20/25-150TH |

38.1 |

0.6~2.1 |

3.3~ 9.5 |

60.3~ 73.0 |

19.1 |

0.6~0.9 |

|

|

20/25-175TH |

44.5 |

0.6~2.1 |

3.3~ 9.5 |

60.3~ 73.0 |

19.1 |

0.6~0.9 |

|

|

25-200TH |

50.8 |

0.6~2.1 |

3.3~ 9.5 |

73.0 |

19.1 |

0.6~0.9 |

|

|

25-225TH |

57.2 |

0.6~2.1 |

3.3~ 9.5 |

73.0 |

19.1 |

0.6~0.9 |

|

|

30-275TH |

69.9 |

0.6~2.1 |

3.3~ 9.5 |

88.9 |

22.2 |

0.6~0.9 |

|

|

40-375TH |

95.3 |

0.6~2.1 |

3.3~ 9.5 |

114.3 |

25.4 |

0.6~0.9 |

|

|

Sucker Rod Pump |

20-125RH |

31.8 |

0.6~2.1 |

3.3~ 9.5 |

60.3 |

19.1 |

0.6~0.9 |

|

25-150RH |

38.1 |

0.6~2.1 |

3.3~ 9.5 |

73.0 |

19.1 |

0.6~0.9 |

|

|

25-175RH |

44.5 |

0.6~2.1 |

3.3~ 9.5 |

73.0 |

19.1 |

0.6~0.9 |

|

|

25-200RH |

50.8 |

0.6~2.1 |

3.3~ 9.5 |

73.0 |

19.1 |

0.6~0.9 |

|

|

30-225RH |

57.2 |

0.6~2.1 |

3.3~ 9.5 |

88.9 |

19.1 |

0.6~0.9 |