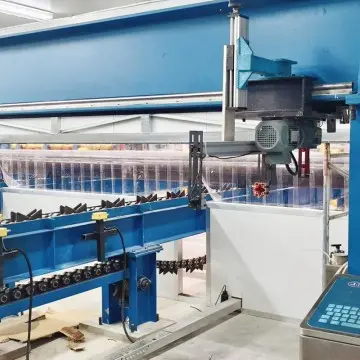

API 7-1 Roller Reamer Manufacturing

Product Application

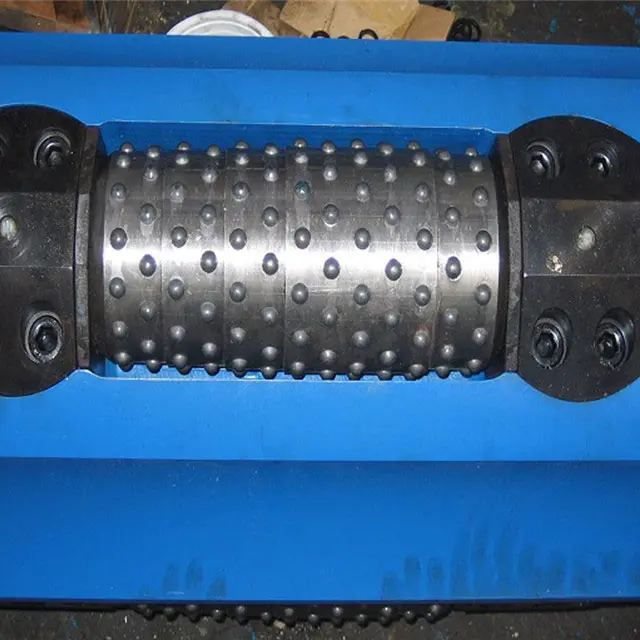

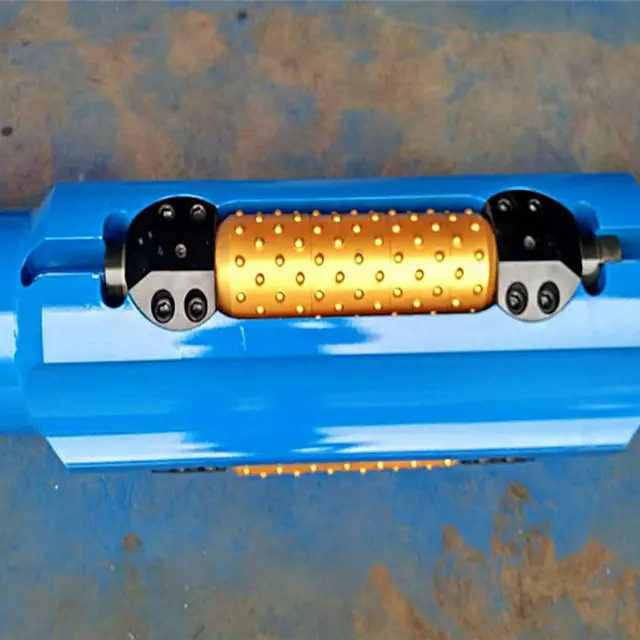

Three different types (T,F and B) of cutters are offered:

Type T: Milled, machined with hard faced sharp teeth for soft formations.

Type F: Milled, machined with hard faced flat teeth, for medium hard formations.

Type B: Equipped with pressed-in tungsten carbide buttons, for hard formations.

Our Roller Reamer has a unique design that enables it to marginally increase the wellbore diameter while still rotating concentrically. It ensures optimal tool placement in the bottomhole assembly, not only guaranteeing maximum tool efficiency but also ensuring there are no negative effects on the bending stresses or contact forces.

Features

Low-torque cutting structure, so that tool will generate less than 5% of the reactive torque generated by the drill bit with which it is used.

One-piece construction, all Roller Reamers are manufactured from a single piece of steel containing material properties. This ensures a strong, robust design that is properly paired with the adjacent drillstring components.

Unique blade layout, our Roller Reamers designed to offer maximum protection to the cutting structure during drillout and increase the efficiency of the blades to agitate cuttings on the low side of the wellbore in high-angle directional applications.

Cost-effective, real-time solution that delivers improved wellbore geometry and reduced trip time

Roller Reamer Specification

Hole Size (inch) |

Connection |

Hole Size(inch) |

Fishing Neck(inch) |

ID(inch) |

OAL(inch) |

Blade Length(inch) |

42 |

8-5/8 REG |

42” |

11” |

3” |

118-130” |

24” |

36 |

7-5/8 REG |

36” |

9.5” |

3” |

110-120” |

22” |

28 |

7-5/8 REG |

28” |

9.5” |

3” |

100-110” |

20” |

26 |

7-5/8 REG |

26” |

9.5” |

3” |

100-110” |

20” |

24 |

7-5/8 REG |

24” |

9.5” |

3” |

100-110” |

20” |

22 |

7-5/8 REG |

22” |

9.5” |

3” |

100-110” |

20” |

17 1/2 |

7-5/8 REG |

17 1/2” |

9.5” |

3” |

90-100” |

18” |

16 |

7-5/8 REG |

16” |

9.5” |

3” |

90-100” |

18” |

12 1/2 |

7-5/8 REG |

12 1/2” |

8” |

2 13/16” |

79-90” |

18” |

12 1/4 |

6-5/8 REG |

12 1/4” |

8" |

2 13/16” |

79-90” |

18” |

8 1/2 |

NC50 (4 1/2 REG) |

8 1/2” |

6 3/4” |

2 13/16” |

65-72” |

16” |

6 |

NC38 (3 1/2 REG) |

6” |

4 3/4” |

2 1/4” |

60-66” |

16” |