4145H&Non-Mag Drill Collar Manufacturing

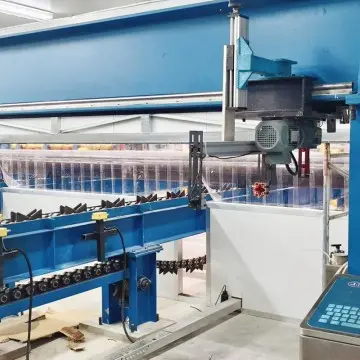

Drill Collar Testing

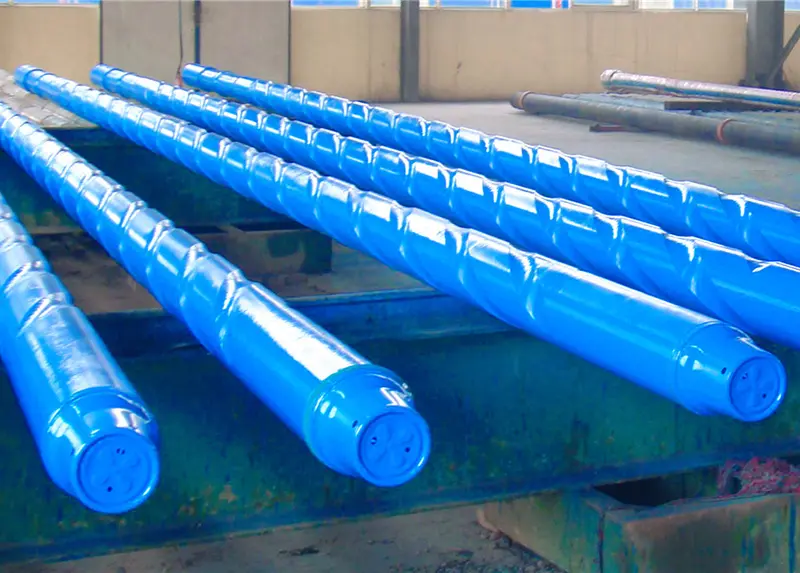

Drill collar Features

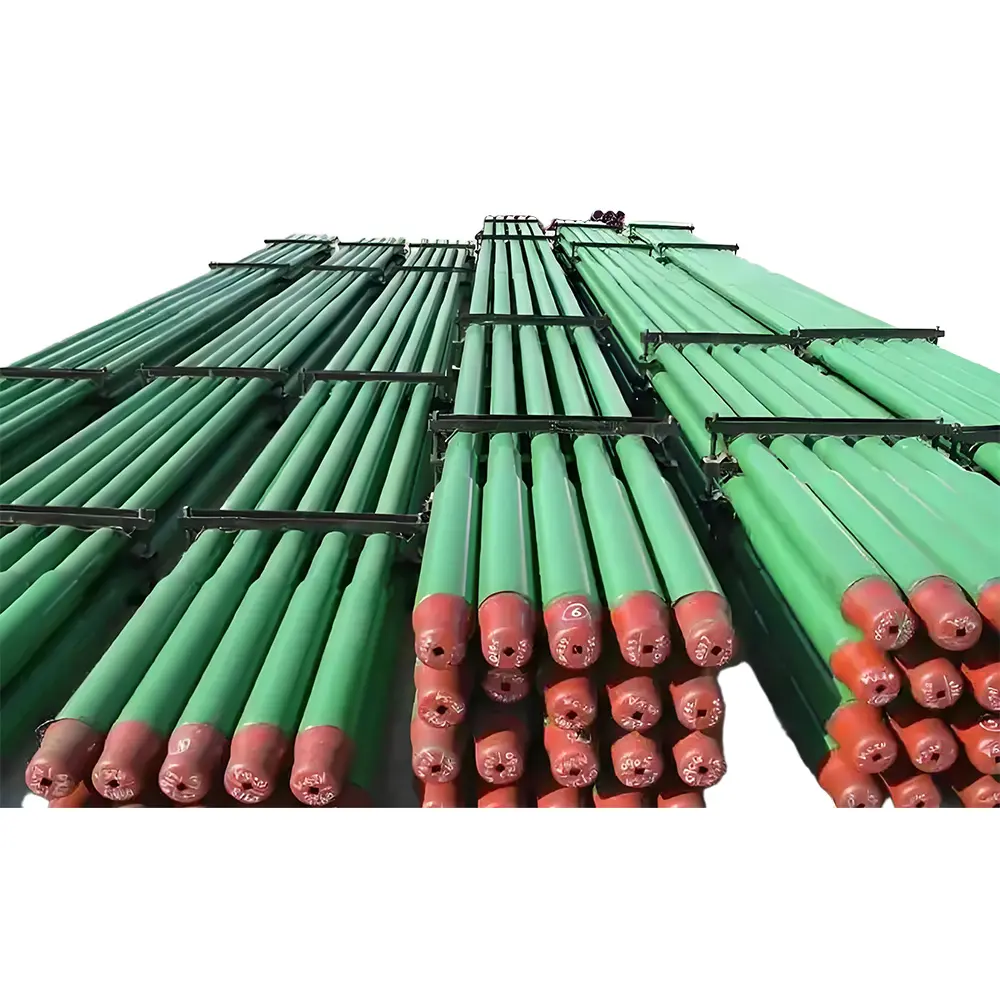

Drill Pipe Features

Size |

O.D(mm) |

I.D.(mm) |

Code |

Thread |

Length(mm) |

3 1/8 |

79.4 |

31.8(1-1/4) |

NC23-31 |

NC23 |

9140 |

3 1/2 |

88.9 |

38.1(1-1/2) |

NC26-35 |

NC26 |

9140 |

4 1/8 |

104.8 |

50.8(2) |

NC31-41 |

NC31 |

9140/9450 |

4 3/4 |

120.6 |

50.8(2) |

NC35-47 |

NC35 |

9140/9450 |

5 |

127 |

57.2(2-1/4) |

NC38-50 |

NC38 |

9140/9450 |

6 |

152.4 |

57.2(2-1/4) |

NC44-60 |

NC44 |

9140/9450 |

71.4(2-13/16) |

NC44-60 |

9140/9450 |

|||

6 1/4 |

158.8 |

57.2(2-1/4) |

NC44-62 |

NC44 |

9140/9450 |

71.4(2-13/16) |

NC46-62 |

9140/9450 |

|||

6 1/2 |

165.1 |

57.2(2-1/4) |

NC46-65 |

NC46 |

9140/9450 |

71.4(2-13/16) |

NC46-65 |

NC50 |

9140/9450 |

||

6 3/4 |

171.4 |

57.2(2-1/4) |

NC46-67 |

NC46 |

9140/9450 |

7 |

177.8 |

57.2(2-1/4) |

NC50-70 |

NC50 |

9140/9450 |

71.4(2-13/16) |

NC50-70 |

9140/9450 |

|||

7 1/4 |

184.2 |

71.4(2-13/16) |

NC50-72 |

NC50 |

9140/9450 |

7 3/4 |

196.8 |

71.4(2-13/16) |

NC56-77 |

NC56 |

9140/9450 |

8 |

203.2 |

71.4(2-13/16) |

NC56-80 |

NC56/6-5/8REG |

9140/9450 |

8 1/4 |

209.6 |

71.4(2-13/16) |

6-5/8REG |

6-5/8REG |

9140/9450 |

9 |

228.6 |

71.4(2-13/16) |

NC61-90 |

NC61 |

9140/9450 |

9 1/2 |

241.3 |

76.2(2-13/16) |

7-5/8REG |

7-5/8REG |

9140/9450 |

9 3/4 |

247.6 |

76.2(3) |

NC70-97 |

NC70 |

9140/9450 |

10 |

254 |

76.2(3) |

NC70-100 |

NC70 |

9140/9450 |

11 |

279.4 |

76.2(3) |

8-5/8REG |

8-5/8REG |

9140/9450 |